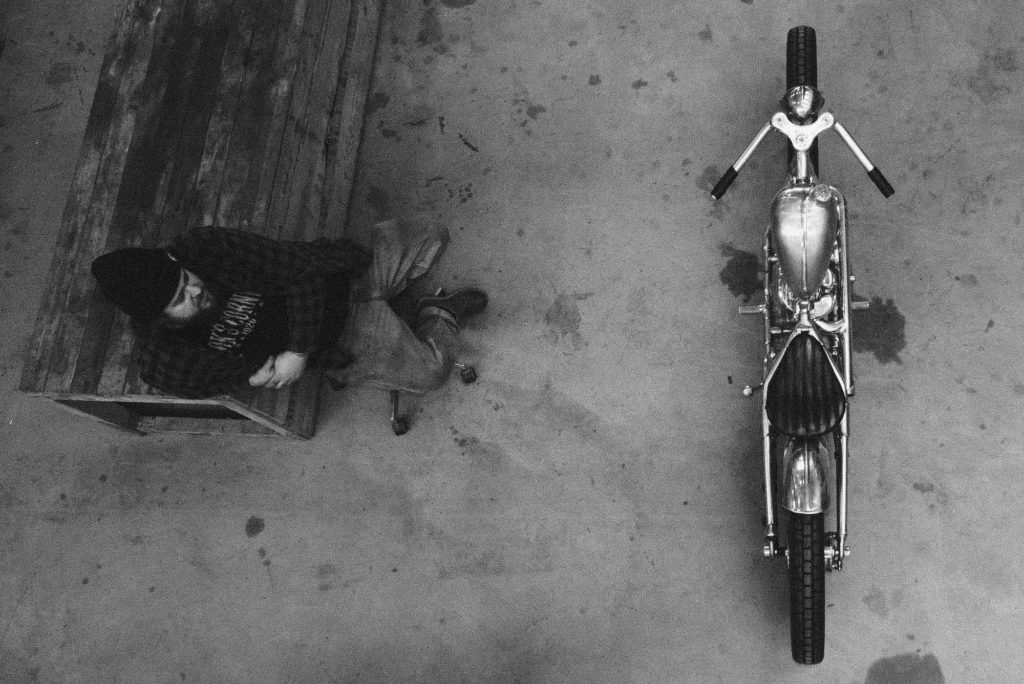

Enrico “Ricky” de Haas doesn’t subscribe to the notion that future-forward electric motorcycles need to resemble futuristic science experiments. In fact, his Wannabe-Choppers AlSi9Mg—handbuilt in his Hüttenberg, Germany shop—is more a throwback than advancement in aesthetics, but that’s what he likes about it. His attitude reflects the laid-back nature of his community in the Taunus foothills.

What’s the inspiration behind building an electric chopper that looks so ‘old school’?

The idea to build a ‘hidden’ electric chopper came about 12 years ago. Back then the idea was not to build it in an old-school way. Battery technology was way more expensive than today, so after failing to find a customer or sponsor for two years we shelved it and I started working on my first Harley project. Then I started casting.

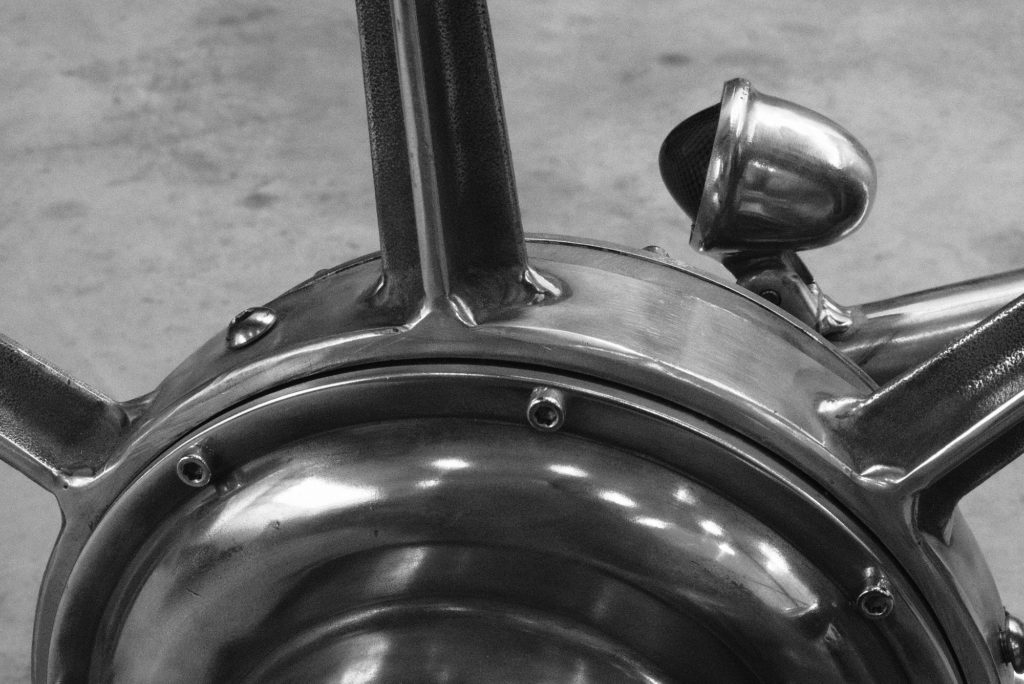

How long have you been casting your own bike parts? The e-chopper looks like a master class in metal casting!

I’ve been obsessed with building a complete motorcycle from scratch since I was 15. This includes everything: frame, motor, transmission with all their internals (even the valve springs) to the tires. This meant I had not just to learn everything about motorcycles, but also everything about the production techniques, as I wanted to make everything with my own hands.

I understand you’re planning another e-chopper that’s more refined and faster?

We started planning the next two bikes on the day the AlSi9Mg was finished. Both will go in the same style direction: one will hopefully be powered with our own ICE and the other will have two very powerful electric hub motors, each several hundred Nm. One in the rear wheel and one in the front. But it’s very tough to find the time and the money to make this happen. A few days ago we ordered a new frame jig to start with the electric bike! Hopefully the next months will be productive.

You recently toured the American custom bike shows; did you get any orders? If so, what would a hard-working woman or man pay for their own Wannabe e-chopper?

The trip to the US did bring us a lot of orders for production and one of parts, but as of today no customer for a bike. But you never know. A bike probably would start at roughly 80,000 euro and will go easily up to 250,000 euro, especially if we build a one-off motor in house.

So we are talking about buying art, I am all for that, electric technology is the segue, it is about artisanal cycle craft.

Fantastic, I want one !!!!

How do I get one ?

Jim Sheppard

shepp4@yahoo.com

Or N2recording@gmail.com