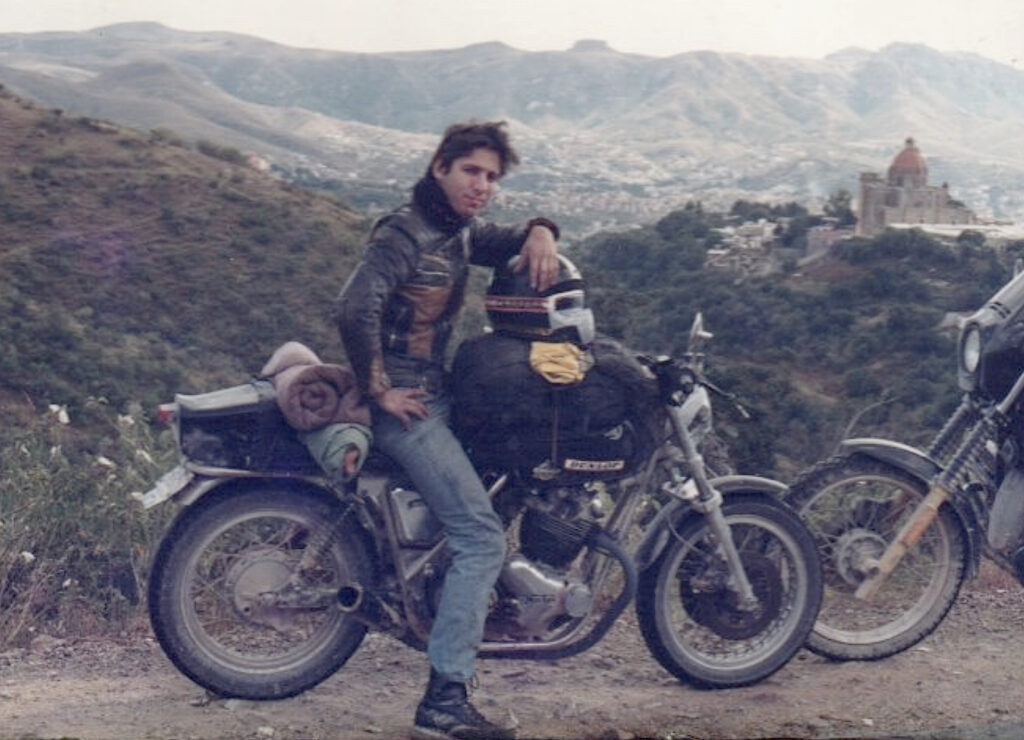

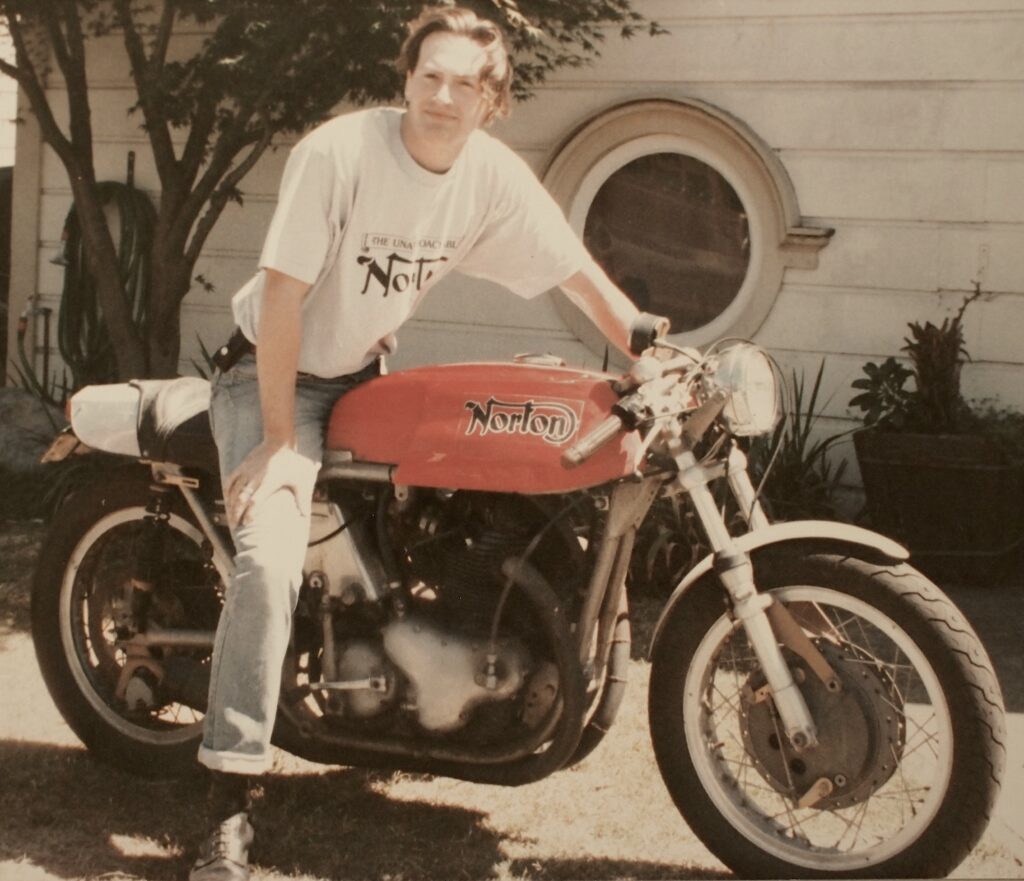

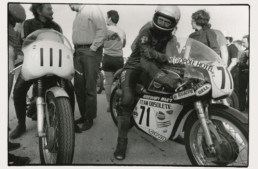

Full disclosure: due to an unpredictable path through life, I have rubbed elbows with, hung out with, ridden motorcycles with, done work with a lot of very famous individuals. Major rock stars, huge television personalities, film stars, and ravishing beauties men tuck themselves into bathrooms to privately celebrate. All have been interesting in one way or another, mostly for highlighting the strange separation of an actual human being with a famous simulacra the world adores. From all these meetings with remarkable men and women, there is only one who consistently astonishes me with a combination of genius, enthusiasm, accomplishment, and humility: Dr. Robin Tuluie. He also happens to be the one I’ve known the longest, as indeed I knew him when, having stenciled the logo of our long-defunct café racer motorcycle club on his leather jacket in 1987. Back then he was Rob the Roadholder, the egghead kid doing undergraduate studies at UC Berkeley, who rode the same Norton Commando on club runs that he campaigned at our local track, Sears Point. He was the same fellow then as now, being enthusiastic with a goofy humor and shy humility, and the ability to dig two layers deeper in a technical conversation than the rest of us, all of whom happened to be fellow alumni of the UC system, and no dummies, regardless our relatively harmless shenanigans aboard obsolete British motorcycles on the late-night streets of our sleepy city by the bay.Dr Robin Tuluie’s meteoric career on two and four wheels

[Note: this article originally appeared in The Automobile magazine in April 2021, with photos by Any Shore. It’s definitely worth checking out the print version, but Rob’s photos (and mine) tell another story…]

An interesting story to say the least . A bit … disjunct and bunny trailed perhaps … but then again how many’ folks lives and careers do follow a straight line without a few detours , jumped tracks etc ? Looking over my 60+ years on this little blue ball ;

( Sound &Recording engineer and designer / musician / composer / instructor / professor / apprentice chef / professional photographer / racer [ 4 wheels ] / audiophile sales and design / theologian apologist [ that ones long gone ] / a couple I cannot mention 😉 / etc etc et al )

… Not many .

Cheers to a man free* enough and willing to follow his muse .. .

😎

* Hint ; ” Money is cheap – Freedom is expensive ” -Hunter S Thompson

Great article and old friend to boot. My older brother worked at MTS in its growth phase as it transitioned from simple presses to computer aided simulation devices custom made for multiple industries. My brother never said much about what he did but converted from electrical to soft ware engineer when I was in college. I would be interested in the design for the mechanical heart. Is it a turbine powered system or valve and piston? Think. Life without a pulse. There are some individuals out there alive right now without pulses. No not vampires. Isn’t science great!

He got to Daytona one year by the money I paid him to rebuild my 1975 Commando. I still have that bike! Haven’t heard from him in decades…