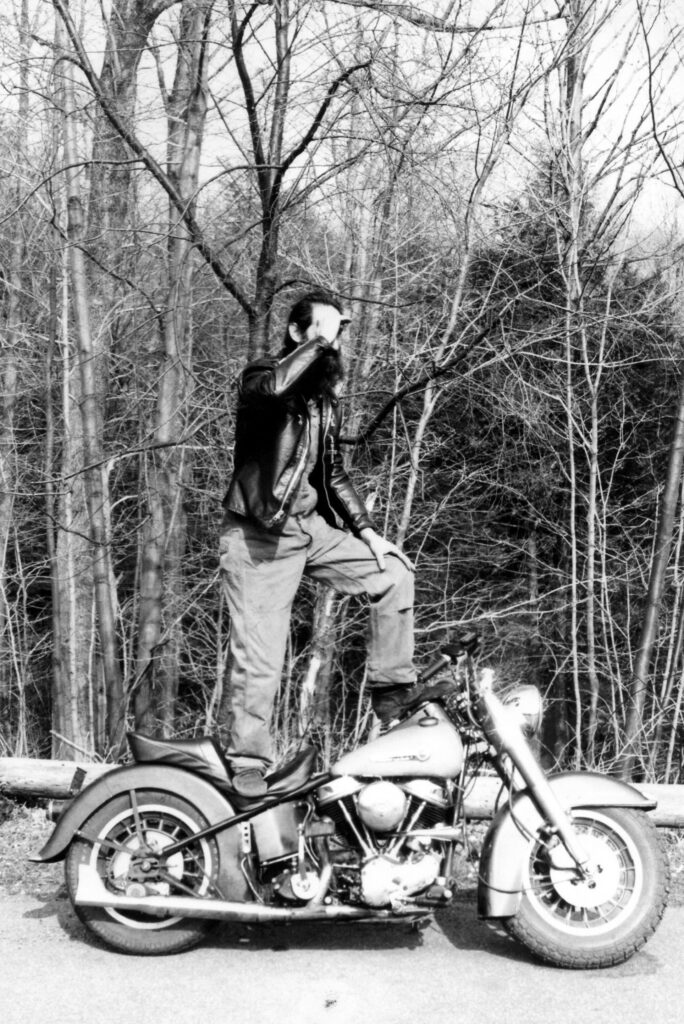

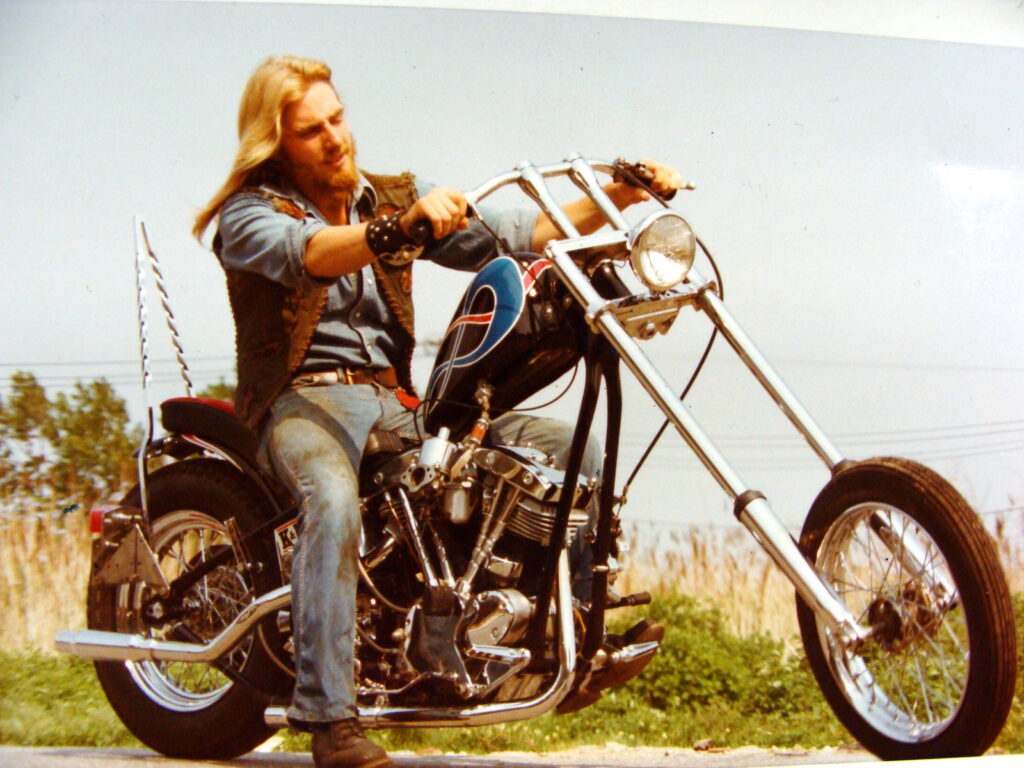

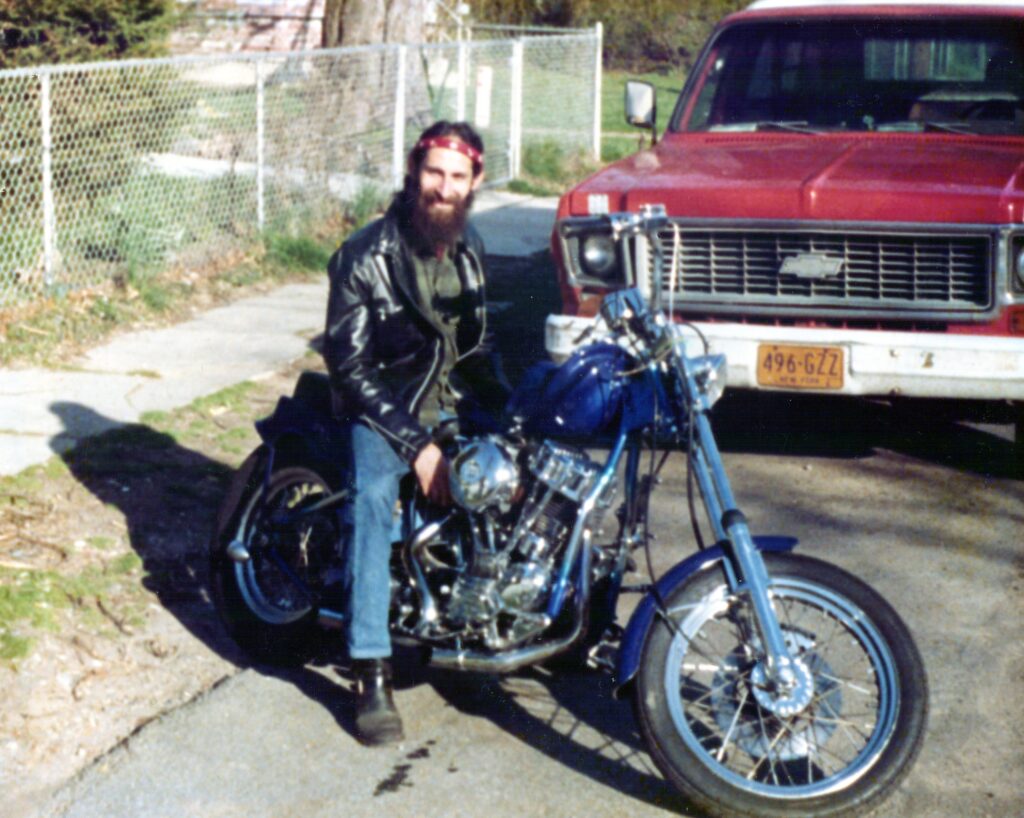

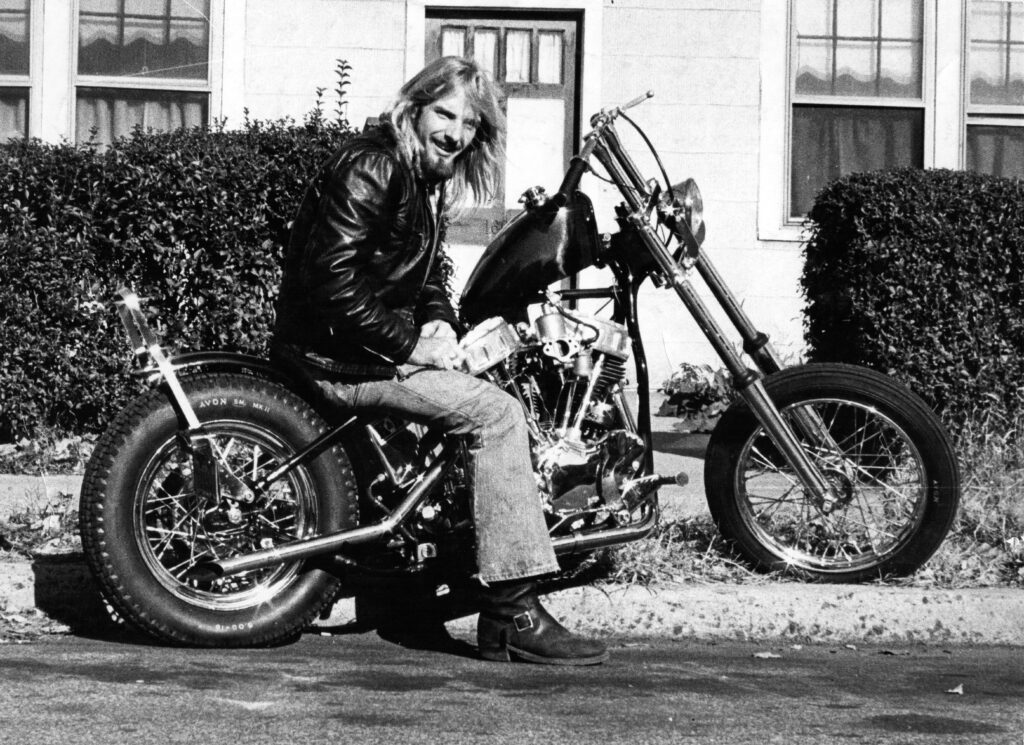

“I feel an attachment to something like a Shovelhead engine. It goes back to where I started from. After market companies still sell parts for these old engines but they don’t know nothin’ about them. They don’t know how to make them run. I like to change the parts around to make them run better. I put the whole valve train from an Evolution on a Shovelhead. They told me I was dreaming. It couldn’t be done. Oh ya? In that case I am going to make a stroker to boot. So I made a ninety-two incher out of a seventy-four. It was a challenge. I’m dreaming? Don’t think so. Fucking thing purrs like a kitten.” – Frank Voto

Lets hope and pray ( to what ever ” Small Metal God ” one bows down before ) that he’s not the last

So come on all you Suburban Urban Hipster Wanna Be;s …. is there just one of yer miserable little pretentious ( bleeps ) willing to step up to the plate of ;

GENUINE AUTHENTICITY

Rather than the pretend version y’all hides behind each and every day ?

Come on Splinkies …. just … one ?

😎

So … probably should commit on Mr Voto’s bikes .

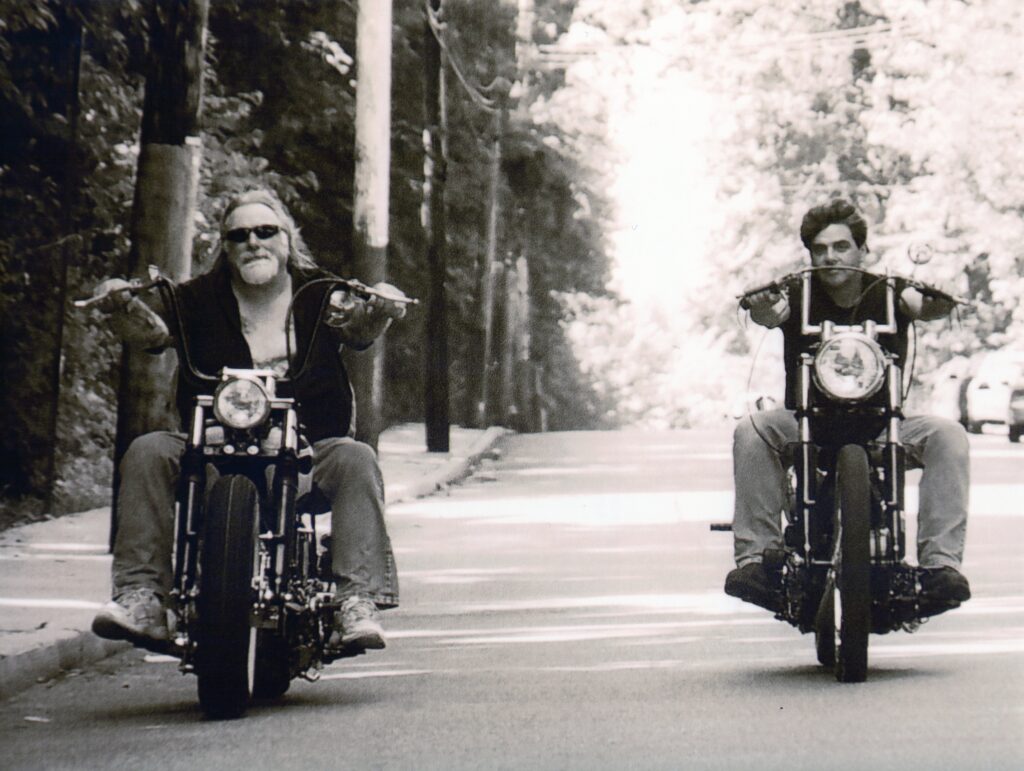

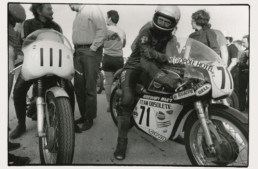

Classic … completely devoid of extraneous B.S. … and most importantly ( unless my eyes and the photos deceive me ) …. completely and utterly ridable … not just as a ‘ bar bike ‘ .. but for as many miles as yer butt can handle .

And THAT … is why we need the likes of Mr Voto around . So that badass … great looking … ridable customs like these will sill be available .. wel into the future … regardless of how much the future tries to crawl up digitals posterior .

End of lecture ….

Rise On … Rock On … Remain Calm ( eff em if they can’t take a joke ) and do … especially you Mr Voto … please Carry On at least until someone else can fill yer boots

😎

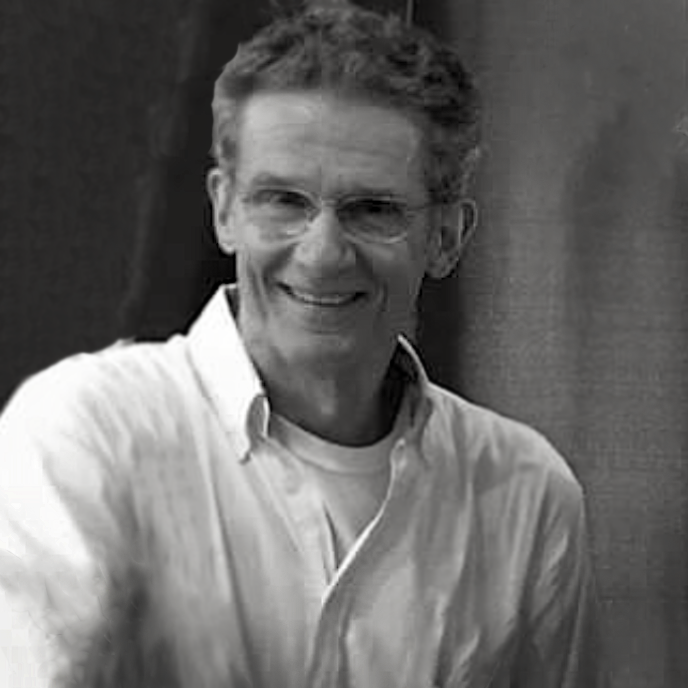

PS; .. RE: Mr McCabe … damn fine article … damn fine subject.. damn fine photos

I grew up in the same era,in my dad and uncle’s shop in the boston area. It sill operates to this day thankfully..As a good friend of mine said recently,”we are becoming an endangered species”….Only one friends indy shop left in my area now that has that depth of knowledge and he is contiunually 3 months out…as we’d say in the old days “keep the faith Frank”…

Good to see some of us are still around. My first bike was a Bultaco Matador 250 I used for hill climbs followed by a big base Scout race bike I found in a shed in Frederick, Md where they used to hold mile flat track races. This was 1967-69. Got my first bike mechanic Job in1970 at a Benelli dealer in Maine. Been doing it ever since. At that time I built my first cafe racer out of a new Suzuki X-6 250 Hustler that the original owner had crashed wasting it cosmetically. It led me directly to road racing. Still have a one man shop at the end of a one lane dirt road up the side of a mountain in Western, NC. Don’t have a web site, don’t do social media. Strictly by word of mouth.

If you ever get up to Maine check out David Laemmle at Carriage Motors in Wiscasset . He’s been into Laverdas and MV for years. Worked for him back in the 70s when I lived up there.