The Swedish Chief: Ola Stenegard

A little back story: the Indian name on two-wheelers predated motorcycle production, but was one of bicycle manufacturer George M. Hendee's product lines. Hendee was a multi-time champion bicycle racer in the 1880s who turned manufacturer in the 1890s, and looked for a reliable pacer motorcycle for his racing teams in 1899. Swedish engineer Carl Oscar Hedstrom, trained as a watchmaker, built lightweight racing bicycles in the 1890s, and turned his hand to making a better version of Count DeDion's ubiquitous F-head motor in 1900. Hedstrom did improve on the motor, but even better, he designed the first 'spray' carburetor that worked reliably, and was a milestone improvement in the motorcycle industry. Unlike everyone else's pacers, Hedstrom's started and ran and finished races, which caught the eye of Hedstrom. A (very lucrative) handshake deal in 1900 was the foundation of a new partnership, with motorized bicycles being produced under Hendee's Indian brand as 'motocycles' from 1901. Thus, a Swedish motorcycle designer founded Indian, and much of the American motorcycle industry, as his motor design was licensed to dozens of manufacturers [Read the Indian origin story here]. The choice of Ola Stenegärd as Indian's new chief designer was thus an elegant closure of a century-old circle, with the very DNA of the brand having a half-Swedish flavor.

Ola Stenegärd is almost three years into his second tour of duty with Indian Motorcycle. As director of product design, he’s in the catbird seat as Polaris shapes and modernizes a 120-year-old brand. I first met the affable and unfailingly polite root beer drinker during the 2017 One Moto Show in Portland, Oregon, when he and the Roland Sands Design crew jammed onto a couch in the old pickle factory. They were starving, and Jean happened to have some of her homemade country sourdough bread. In 2018, Henri and I hung out with Ola at the Sturgis Rally, watching flat track racing on our way to Bonneville Speed Week. With product development cycles beginning well before the consumer gets an eyeful, it would take awhile before we could see Ola’s DNA appear on an Indian; he spent 15 years at BMW Motorrad, giving us the R nineT before looking West to Medina, Minnesota in March 2018.

Ola lives and creates on Gotland, an island surrounded by the Baltic Sea five hours by ferry south of Stockholm. It’s been a year since we hung out at The One Moto Show, and with the recent Indian Chief cruiser line introduction it was time to talk. It’s not everyday that a brand launches something on the 100th anniversary of the original.

"Been a tough year, no doubt. But we’re a small creative team and we quickly doubled down, adapted and adjusted. Our boss - design VP Greg Brew - has been awesome and supporting us 100 percent around the clock! So we started doing more rapid prototypes, even 1/2 scales, that we could send and print out at our different locations and in our different studios in the EU and US. This allowed us to get a feel and even sign off design proposals without losing speed and agility. We also dove deeper into using video, clay models as well as extensive CAD spins.

Usually there’s a lot of traveling, but I gotta admit that COVID brought a silver lining for me personally that I’m allowed to see my kids and family every day. Our global work setup also made the transition quite easy. And now I have had time to spend the mornings in my shop too! I’m still a garage rat, and if I can’t cut some shit up or weld something, the day is not really well balanced!"

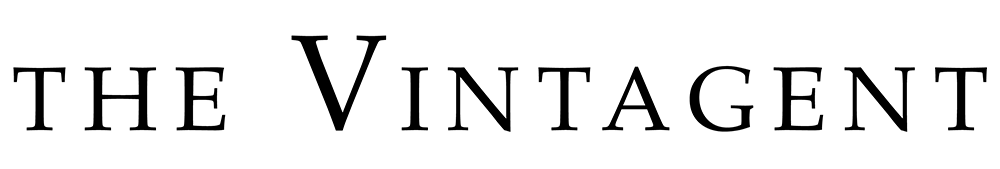

"Everything started with the frame. We literally built the it old-school style, motor on a block, bending tubes. When the frame sits right on the wheels, tins and seats come easy. Then we went into traditional clay modeling. No CAD can ever replace the human hand. But make no mistake: CAD has its right time and place too! Super important and we had a great team that supported the whole project wholeheartedly! But the frame was the key: with all the bones in the right places, it looks great naked as well as fully dressed.

Also, customizing was key. We can’t make every single motorcycle perfect for every single customers. But what we can do is create the PERFECT base for all riders to make it their own! The perfect blank canvas! Bottom line, it’s all about keeping it simple. It’s very easy to complicate things these days. But keeping it simple in itself complicated."

"We took a lot of inspiration from different eras of the American moto culture we love and kinda nerd out on and basically what we grew up with. It kinda celebrates the era as well as all the guys/gals that carried the flame of the chief from the Fifties until the early 2000s by customizing, chopping and bobbing original Chiefs, and thus keeping the legacy alive! I dreamed of this new Chief for 20 years, since I worked for Indian during the Gilroy times.

The story of the three flavors of the new Chief in a nutshell:

We wanted the Chief to be the bare bone bad-ass base for the whole family, with mids, narrow bars, cast 19”/16” wheel combo and stripped down fork and shocks. Kinda rooted in the late Seventies, early Eighties when Arlen Ness, Perry Sands and Dave Perewitz started experimenting with cast wheels and mid mounts and spiced up their scoots with more performance parts.

• The Chief Bobber takes a lot of inspiration from the mid Sixties: kinda Dave Mann meets a young Perry Sands and visits Ben Hardy who all gets cast in an early biker flick. The timeless style that brings us to our knees: 16”/16” wheels, mini apes, floating solo seat, covered fork and shock for that righteous ol’ school vibe.

• With Superchief we thought it should feel right at home in Hollister 1947 or The Wild Ones. When vets and blue collar cats and chicks were true rebels riding bad-ass sickles! We tried to reflect that kinda spirit: ride hard to get there, ditch the bags and screen, shred main street to take a turn on the dirt oval before going bonkers Saturday night. Sunday, you collect the pieces and pack it all back up and ride on back home. An homage to the style that made bobbed and cut-down Chiefs legendary back in the day.

The common thread is that all these bikes gravitate toward the club-style bikes of their specific era. Paul d'Orléans [publisher of TheVintagent.com] and I talked a lot about this, and he is totally right: throughout the years these were the bad-ass, ride hard, purposefully-looking custom bobbers and choppers we always tend to gravitate to. Not show bikes per se, but still really good looking rides, right? They represent the kinda bikes that just stays burned into your memory forever."

"We’re aiming for the end of April/beginning of May."

Q: What’s your advice to aspiring motorcycle designers?

"Sketch, sketch and sketch. And ride motorcycles! Then sketch some more. And let no one take your dream away!"

The Current: Saroléa Melds Google AI Into MANX7

Belgian pride is hard to find in the motorcycle world. Xavier Siméon was the first Belgian to race the premier MotoGP class in 17 years when he piloted his Reale Avintia Ducati during 2017, and only the third Belgian rider to win a motorcycle Grand Prix, after Didier de Radiguès and Julien Vanzeebroeck at the 2015 German Grand Prix at the Sachsenring.

From its humble beginnings in 1901—when the first Saroléa motorcycle was created by bolting a 1.5 hp 247cc engine and a tank onto a Saroléa bicycle—through 1973, when the company ceased all production, Belgian pride was fairly constant for Saroléa. In 2010, the Saroléa name returned when twin brothers Torsten and Bjorn Robbens acquired the brand and refocused production on all electric machines [their grand uncle was André Van Heuverzwijn, a successful Saroléa factory motocross racer in the 1950s]. A new production facility was established near Ghent, Belgium.

Recently, the Ghent-based Belgium duo have partnered with ML6 to add artificial intelligence to its MANX7 model, which we wrote about on July 21, 2018.

AI inside

"To this day, artificial intelligence is made possible by first sending all of a system’s data via the internet to the cloud,” said Nicolas Deruytter, managing director of ML6, which works closely together with Google Cloud. “Then, based on that, models are initialized (by letting them learn) and the trained models are then sent back to the machine. Thanks to the Edge TPU, the AI (with its 'trained models') can intervene fast and more efficiently. In addition, each individual system can learn more."

For 2019, the Saroléa MANX7 will come equipped with ML6’s Waizu software, which was initially developed for a far-reaching optimization in industry processes. This Belgian partnership means Waizu is now being integrated into a motorized vehicle for the first time and aims to squeeze every last drop of autonomy and power to the benefit of the MANX7. Saroléa also intends to make the technology available to other manufacturers through a future platform.

The Tech: Google's Edge TPU

ML6’s platform combines its expertise in machine learning for predictive maintenance with pioneering research in the field of reinforcement learning and Google's latest technological developments in hardware and cloud. This new software was developed for industry processes and allows companies to optimize numerous processes. They use Google's Edge TPU, a processor that was specifically developed for artificial intelligence, and installed it on the MANX7 engine itself.

According to Saroléa, countless parameters in a vehicle can be mapped and optimized but that would be impossible to do manually. And, data can vary according to every single situation and location. How is power controlled? What temperatures are reached inside the vehicle? How is the battery managed? The chip captures and interprets. Subsequently, the software determines the best settings. This is how Saroléa and ML6 plan to focus on more autonomy, predictive maintenance and an improved battery performance.

"On the one hand, this allows to increase the vehicle’s efficiency, leading to more autonomy as a direct result,” Bjorn Robbens explained. “On the other hand, we also extend the battery’s life cycle. The way in which a battery is used and charged helps determine its lifespan. If we can evolve towards a model in which the battery is charged and used in ideal circumstances, its autonomy could improve by 20 to 40 percent and the battery will last for years."

The future of AI

The Robbens boys understand that the potential of this technological application is enormous and reaches far beyond the motorcycle world. That is why Saroléa intends to market their technology in the near future and make it available to the entire automotive sector via a platform.

"Buses, trucks, bicycles, automated guided vehicles; we are looking at the bigger picture here,” Bjorn Robbens added. “We want to package the technology and know-how we have built up with our partner, ML6, and offer an off-the-shelf solution to other OEM players.”

A Year of Living Dangerously

The former punk rock girl who smoked and danced and got straight A’s until I came into her life in 1986 was perfectly happy sharing rides on the back of our 2003 BMW R1150RT. The Bavarian machine has crossed the country, attended a couple Quail Motorcycle Gatherings, crossed the Golden Gate Bridge and led countless Sunday Moto Club rides with her as my co-pilot.

The road from CVS to the central California coast was serendipitous at best. Jean had just met Alp Sungurtekin and his wife Jalika at The Quail, when talk of racing at the Bonneville Salt Flats was fresh on their minds. I first met Alp and Jalika at the Petersen Museum for the Custom Revolution exhibit a few weeks prior, and planned on interviewing him for Cycle World. Land speed racing was new for me, and as I learned after visiting Alp and Jalika at their home workshop in Shadow Hills near Burbank, California, Bonneville is its own world full of characters and mad scientists.

During dinner at a Los Angeles restaurant with Jenna Stellar in mid June, the Hollywood costumer asked Jean if she had considered getting her motorcycle endorsement. “Well,” Jean said with a smirk and a sideways glance at me, “our son Henri has offered to give me some coaching on his SYM Wolf Classic, a single-cylinder 150cc bike he bought in 2016.”

In early August Henri and I rode Harley-Davidsons from the H-D headquarters in Milwaukee, Wisconsin, back home to California. Along the way we visited family, then hung out for half a day at Sturgis, kibitzing with Roland Sands, Indian Motorcycle designer Ola Stenegärd and Stellar before watching American Flat Track racing at the Buffalo Chip fairgrounds. The following weekend Henri and I rolled into Wendover, Utah for Bonneville Speed Week where Alp was preparing his machine with the aim of 200 mph in 100-plus degree heat. Stacie B. London, Shinya Kimura and several tuners-racers attempted to tame the salt that weekend, with varying degrees of success and challenge.

As we watched Alp prepare his pit, Bryan and Christine Thompson drove up in a rented RV, wearing white boiler suits and Vans. I recognized Bryan from Instagram, and they kindly invited us inside the RV to duck out out the scorching sun. We quickly bonded, and two weeks later met again at the Roland Sands Design Moto Bay Classic in San Francisco, where Bryan was displaying his ‘Red Arrow’ Triumph custom.

She’s also a co-founder of the Sunday Moto Club—where all bikes are welcome and kindness is encouraged—and has asked several members which bike they’d recommend. She researched and read about several lightweight adventure and touring bikes, in no rush to decide. She’s attended the One Moto Show, the Handbuilt Show and toured both the Harley-Davidson museum in Milwaukee and Robb Talbott’s museum in Carmel Village, California, so she’s laid eyes on some of the finest bikes in the world. The riding season in northern California never ends, so there’s certainly less pressure.

Then on December 12 Thompson posts his Thruxton scrambler for sale on Instagram. He bought it from the famous Wilson’s dealership in Fresno with two miles on the odometer on a day when he was merely tagging along with a friend on the hunt for a Bonneville. The stock pipes, seat, handlebars, tires and several other parts were replaced by the former speedway racer, including the tank, which he painted and had pinstriped by a signmaking friend.

I sent him an email, and 45 minutes later the phone rings.

“Jean keeps coming back to Triumphs, Bryan, and I think yours is the one,” I told him. I showed Jean the video and photos posted by Bryan, and told her I’d drive her down to the town of 17,716 near Pismo Beach if she wanted to check out the bike and ride it.

A week later, the Thruxton scrambler is sitting in our garage, making friends with its Italian and German stablemates. We’re adding offset bar risers and replacing the tires, and while Christmas came a week early for the former punk rocker from Milwaukee, Jean knows how things tend to work out if one is willing to live dangerously and make friends.

The Current: Fly Free Introduces Classic and Desert E-Bikes

Long Beach, California is home to a new e-Bike company: Fly Free Smart Motorcycles.

Some Deets

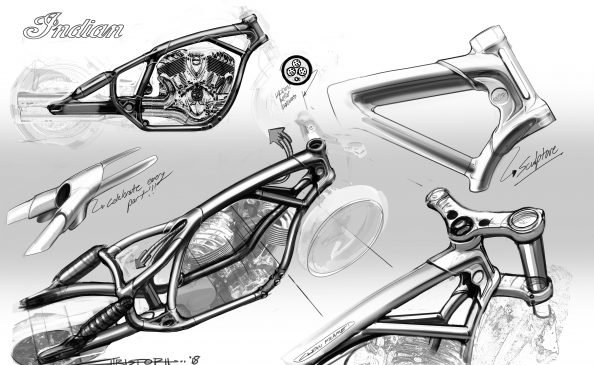

Two Fly Free models have been introduced, the Classic and Desert. Eighty different color and accessories options will be available, according to the company. The bikes will use one or two battery packs as ordered, and offer two settings: one with 50-mile range reaching a top speed of 40 miles per hour (one battery) and the other one with 100-mile range that can reach the maximum speed of 50 miles per hour (two batteries).

A full battery charge will take about eight hours and, according to Fly Free, after 700 cycles the removable battery still maintains 70 percent of its initial capacity. That should equal many years of regular use, unless you're a weed/pizza delivery person in Venice Beach, in which case, the batteries might need more love.

Verdict?

The challenge for every emerging e-bike company lies with delivery, cost, range and service after the sale. While we applaud all efforts made to get more e-bikes on the streets and in the dirt, we need to feel confident a new company will have our back after purchase, and might be around longer than next year. We'd love more information on how Fly Free will provide service after sales.

The Current: The Copenhagen Wheel - An Instant E-Bike

Assaf Biderman teaches at the Massachusetts Institute of Technology, where he’s also the Associate Director of the SENSEable City Laboratory, a research group that explores how new technologies are changing the way we understand, design and ultimately live in cities. Biderman focuses on partnerships with city government and industry members worldwide to explore how distributed and embedded technologies can be used to improve livability in cities and create a more sustainable urban future.

Why a Wheel?

Copenhagen Wheels are custom built to fit each customer’s bicycle, and are compatible with steel or aluminum bicycle frames with rear rim caliper or cantilever (non-disc) brakes. The Copenhagen Wheel is available in both single and multi-speed versions (supporting a 7-, 8-, 9- or 10-speed Shimano/SRAM-compatible (external) multi-speed cassette). Copenhagen Wheels come in two wheel sizes—700c or 26-inch—with either road, hybrid, or mountain bike tires. Rim colors are silver or black.

How does it work?

The Copenhagen Wheel contains a custom brushless motor, advanced sensors, control systems, and a lithium-ion battery, all enclosed within the red rear wheel hub. The control system interfaces with a range of sensors measuring actual torque, power, cadence, pedal position, and acceleration to monitor a rider’s effort when pedaling. The Wheel responds to a rider’s inputs by providing the appropriate level of assistance at each moment, creating a seamless ride experience.

Copenhagen Wheel - Product Development Update from Kobie Flashman on Vimeo.

Of course there’s an app!

In order to gain assist, the Wheel must be connected to Superpedestrian’s Wheel iOS or Android app. The Wheel App tracks rides and calorie information, and allows riders to toggle between ride modes such as Turbo, Eco, and Exercise. A smartphone also acts as a digital key, activating the Wheel automatically when ready to ride, and communicating with the cloud in real time. A self-diagnostic safety system monitors components within the Wheel and proactively responds to events within milliseconds, protecting both rider and Wheel. Superpedestrian sez it releases frequent updates to the Wheel App.

Wheel + Bike option

Superpedestrian offers complete bikes through partnerships with Marin, Public, Montague, Fyxation, Tern, Cinelli, and Fortified. Not sold on the concept? Superpedestrian also works with over 260 independent bicycle retailers across the U.S. and Europe to provide demos, maintenance, and installation services.

The Current: Eva Håkansson's Quest to Break 400 mph With Green Envy

Breaking a land speed record by reaching 255.122 mph in an electric motorcycle of her own design and construction isn’t enough for Swedish mechanical engineer and lecturer Eva Håkansson. After becoming the world's fastest woman on an electric motorcycle in 2014, 2016 and 2017, the 37-year-old resident of New Zealand aims to break 400 mph by 2021.

“About 80 percent of the hours, blood, sweat, and tears that went into the KillaJoule are mine,” Håkansson told Guinness World Records in 2016. “The rest was built by family and friends. The motorcycle was built from scratch in my two-car garage behind my house."

“With a theoretical chance at 265 mph, I turned out on the track deciding to give it everything it had. The speedometer in the bike `only’ showed 259 mph, but I knew that it was a bit pessimistic (the front tire grows at speed and offsets the speedometer reading a little bit), but I wasn’t sure how much. When the timing folks reported on the radio that we had run 270.224 mph I knew this wouldn’t be my last year of racing. I was the world’s fastest female motorcycle rider, and 300 mph was simply too close to quit now.”

In 2016 Håkansson again broke the land speed record at Bonneville with 248 mph, and reached 255.122 mph in 2017. Speed and motorcycles are part of her DNA, literally; her father, Sven Håkansson, used to build motorcycles and her mother was the family mechanic. In 2007 she and her father converted a Cagiva Freccia C12R-90—an 125cc Italian two-stroke motorcycle—into an electric version with equivalent performance to the original combustion engine motorcycle. Their ElectroCat passed the registration inspection and became the first street legal vehicle in Sweden in January 2008.

“How does it feel running for a speed record? That’s the second most common question I receive,” she added. “The most common is `How fast is it?’ The speed question is easy to answer, the other question is much more difficult.

“I’m not an adrenaline junky, actually quite the opposite. While it is definitely an experience of a lifetime, and a very privileged position, I find the record attempt runs very stressful and at times outright scary. It is quite claustrophobic and uncomfortable. I am strapped in and can’t move. The pressure to set a record is enormous, and the world is watching. When we get to the starting line, I sometimes just want to run away and go home. Or take a nap because I am exhausted from actually getting everything done on time.

“The drive itself is really short, just a few minutes, but can be quite an experience. Driving the KillaJoule is really easy, pretty much anyone could do it (provided that you are maximum 5-foot-2). You look toward the end of the track, twist the throttle and try to stay approximately in the middle. When you pass the finishing line, you roll off the throttle and push the brake chute button. You slow down over about a mile or two, and when you reach one of prepared access roads you turn off the track. That’s it. It’s the easiest part of my `job.’ But that said, it certainly isn’t free from emotions.

“It is known that stability problems can occur very suddenly, so it is quite nerve-wrecking. The vehicle is also extremely tight and claustrophobic. To be honest, that alone took a while to get used to. The relentless desert sun beating down doesn’t make it any more pleasant. But, at the same time, the feeling when everything works flawlessly is like magic. Years of work finally pays off, and it is like time stops. When I have finished a run, all my nervousness and discomfort quickly vanishes and is replaced by a huge grin. I say, `Well, that was easy, let’s do it again.’

Green Envy Replaces KillaJoule

According to Håkansson, Green Envy will be a battery-powered and streamlined sidecar motorcycle and it will look very much like the KillaJoule. However, there will be some major differences. First off, Green Envy will also have more than twice the power of KillaJoule, targeting over 1,000 horsepower; 1 megawatt equals 1,360 hp.

It will be built with the goal to become the world’s fastest motorcycle, electric or otherwise. The overall motorcycle record is 376 mph, set by Rocky Robinson in 2010. In order to fit the larger drivetrain, Green Envy will be about three feet longer than KillaJoule, which means about 23 feet. The cross-sectional area will stay the same, and the aerodynamics will be improved.

“There will also be a lot of subtle changes improving performance, handling, and reliability,” she explained. “Or simply speaking, we will learn from all the mistakes we made building the KillaJoule.

Green Envy Timeline

2019: Construction, in Auckland, New Zealand.

March 2020: First start at Lake Gairdner salt flats in South Australia, under the sanctioning of the Dry Lake Racers of Australia. “The goal is to make a safe, successful run and keep the rubber side down and the shiny side up,” Håkansson said. “A speed of 200+ mph would be considered a success. Anything higher than that would just be bonus!”

August 2020: “If time and budget allows, it would be possible to race the Green Envy at Bonneville as well, but that would require very generous sponsors.”

March 2021: “Back at Lake Gairdner salt flats. Target: 300+ mph, perhaps even 400+ mph if the planets line up and the angels are singing. (Yes, everything has to work perfectly for this to happen, that’s why it takes so long to prepare).”

The Current: BigRep 3D Prints NERA E-Moto

Additive Manufacturing became part of our lexicon on October 15, 2018 when we spoke with Tarform Motorcycles co-founder and designer Taras Kravtchouk. The Swede and his American partners introduced a bike to mixed reviews, but something beyond aesthetics was at play: will the dawn of additive manufacturing jumpstart 3D-printed electric motorcycle production? Germany’s BigRep—with offices in Massachusetts and Singapore—believes so.

"These exciting prototypes not only demonstrate the unprecedented capacity of FFF large-scale 3D printing technology in AM,” said BigRep GmbH CEO Stephan Beyer, PhD. “They also emphasize our unique ability as the market’s innovation and thought leader to bring cutting-edge technologies from design to reality, providing a market value added lead for our industrial customers.”

All NERA parts, excluding electrical components, were 3D printed, including tires, rims, frame, fork and seat. Breaking from traditional design, mechanical engineering and manufacturing, the engineers focused on creating a bike for large-format FFF technology. NERA features airless tires with customized tread, a lightweight rhomboid wheel rim, flexible bumpers (instead of suspension) and the electric engine, which is fitted in a customizable case.

The Current: Cake Making Waves

As we reported on January 25, 2018, Swedish gadget heads at Cake 0 Emission not only introduced its electric off-road motorcycle production concept and a new category, Light Electric Off-Road Motorbikes, it fully delivered 50 limited-edition bikes to international customers in nine months. And man, did it sweep up design awards across multiple categories and industries, including the highly prestigious (and historically anti-motorcycle) Outdoor Retailer Innovation Awards.

"When Liz Ferrin told us at our book launch that she was organizing the Innovation Awards, and our cover girl Cake was nominated at the world's biggest outdoor industry event, it seemed like kismet, and I knew we needed to be there. Clearly, things are changing in the outdoor world as much as in motorcycling, because the outdoor industry is notoriously hostile to off-road motorcycles. But with the flood of electric mountain bikes and now e-trail bikes, attitudes are softening...although I did hear of one judge on the Industry Awards panel who cursed the Cake; 'What's that F**KING motorcycle doing here?!' Which pretty much sums up why no motorcycle industry folks have ever attended! But, we're happy to be trailblazers, and met serious players in the industry, who were curious why we had come. I explained it seemed a no-brainer: the ADV sector of motorcycling is enormous, and they use exactly the same outdoor gear as bicyclists or backpackers. The e-ADV/outdoor industry hookup is inevitable, and the door is wide open, though nobody saw it."

Are Waymo Smarts Needed to Protect Motorcyclists?

At 7:19 a.m. on October 19, 2018, the rider of a 2007 Honda Rebel made the mistake of passing a vehicle on the right on El Camino Real in Mountain View, California during heavy commuter traffic. Call it a rookie mistake or hurried negligence, but there was more at stake on that Friday morning in Silicon Valley that sent the rider to the hospital.

The difference between this collision and others was that the Chrysler Pacifica was a Waymo Autonomous Vehicle. Before the passenger vehicle cut in front to avoid the box truck, the Waymo vehicle was in self-driving mode. Acting on instinct, Waymo's test driver took manual control of the AV, disengaging from self-driving mode and colliding with the motorcycle.

Waymo reports a decade of testing over 10 million miles on city streets and private facilities. In a recent corporate blog written by CEO John Krafcik, he admitted that the AV driver took the wrong course of action.

“Testing on public roads is vital to the safe development of self-driving technology, and we’re sorry that a member of the community was injured in a collision with one of our cars,” he added. “We recognize the impact this can have on community trust. We hold ourselves to the highest standard, and we are always working to improve and refine our testing program.

“As professional vehicle operators, our test drivers undergo rigorous training that includes defensive driving courses, including guidance on responding to fast-moving scenarios on the road. However, some dynamic situations still challenge human drivers. People are often called upon to make split second decisions with insufficient context. In this case, our test driver reacted quickly to avoid what he thought would be a collision, but his response contributed to another.”

According to the DMV permit, Waymo will be able to test around 36 self-driving vehicles without a driver in Palo Alto, Mountain View, Los Altos, Los Altos Hills, and Sunnyvale. Waymo employees will be the first to take rides in the unmanned vehicles. The self-driving company has been allowed to test autonomous vehicles with safety drivers since 2014, one of 60 companies that are authorized to do so, the DMW said.

But a report from The Information (“Waymo’s Big Ambitions Slowed by Tech Trouble,” August 28, 2018) suggested Waymo's self-driving technology struggles with more driving tasks than the Mountain View company has indicated. The publication said Waymo vehicles have difficulty making unprotected left turns, distinguishing between individuals in a large group, and merging into turn lanes and highway traffic, among other trouble areas.

“Incidents like this are what motivate all of us at Waymo to work diligently and safely to bring our technology to roads, because this is the type of situation self-driving vehicles can prevent,” Waymo CEO Krafcik wrote. “We designed our technology to see 360 degrees in every direction, at all times. This constant, vigilant monitoring of the car’s surroundings informs our technology’s driving decisions and can lead to safer outcomes.”

How Waymo tech works

As motorcyclists, should we take comfort in the idea of true driverless vehicles deciding what’s best for us, even when one of our own used poor judgement on a cold Friday morning in October? Would the Waymo van’s AI made the right decision to avoid colliding with the Honda Rebel?

The Current: Zero Ramps Up, Alta Shuts Down

In a span of seven days, two San Francisco Bay Area electric motorcycle manufacturers made the news for completely different reasons.

No official comment has come from Alta management. In fact, nothing on the corporate website reflects the recent shuttering of the business.

Zero, on the other hand, has been hard at work refining its latest offering of six models.

Earlier this year the producers of Keanu Reeves’ John Wick 3 vetted three electric motorcycle makers for a critical scene in the movie, due out in May 2019. Wick (Reeves) on horseback will be battling the bad guys on Zeroes through a city street at night, beating out Alta and Energica for movie stuntman bragging rights.

Dual sport is Zero’s focus for 2019, with the entry-level $10,995 Zero DS ZF7.2 now boasting 35 percent more horsepower and an 8 percent higher top speed. At 96 pounds lighter than its longer-range counterpart, this model could be an ideal commuter during the week and a nice whip for weekend adventure.

The new $13,995 Zero DS ZF14.4 extends its range by 10 percent over the 2018 model by using the same battery as the premium Zero DSR. This allows the 2019 Zero DS to be configured by adding the $2,895 Power Pack to stretch the range to 204 miles in the city and 97 miles on the highway.

The $16,495 Zero DSR has received several technological and cosmetic changes for 2019, including 116 ft-lb of torque, a dual-sport windscreen, tank grips, hand guards and a 12V accessory socket.

Former Buell designer and longtime Zero CTO Abe Askenazi has been leading development for nearly nine years, and it’s been a steady increase in power, range and line extension since he took over design in 2011. And he’s jazzed to be expanding Zero’s dual sport offering.

Not wanting to ignore the rest of the lineup, Zero’s $10,995 entry-level and lower weight S ZF7.2 now offers the same 35 percent performance jump as the base model Zero DS. The new $13,995 longer-range Zero S ZF14.4 travels 10 percent farther than last year and can be configured with a $2,895 Power Tank to deliver the lineup’s longest range with up to 223 miles in the city and 112 miles on the highway.

Pioneering tech

Zero’s industry-first “Long Term Storage Mode” automatically puts the bike into a low-power mode to optimize battery state-of-charge and further improve long-term battery health. According to Zero, its 2019 models are available in select dealerships around the world and will begin shipping to customers immediately.

The Current: Tarform Electric Motorcycle Blends Swedish And American Design

Opening a motorcycle brand in Brooklyn, the global hub of cool, has been a dream of several e-bike manufacturers: there's talent to spare in the NYC region, and a strong motorcycle culture too. Tarform is the latest e-bike brand to open up shop in BK, but their team isn't strictly local, with a Swedish designer working with the Brooklyn manufacturing hub. They're currently hand-building a limited run of collector bikes in New York, with prices starting at $28,000, and concurrently accepting pre-orders for a production run with an estimated manufacturing date of late 2019. Retail pricing for the mass version will start at $18,000: complete information will be released shortly.

So who is behind Tarform? Check out the video below, then read our exclusive interview with chief designer Taras Kravtchouk.

Taras, you mentioned your intent is to ‘revive the classic form, and unite it with modern day technology to create a new riding experience.’ What design and engineering ingredients are you including to reach that goal?

Taras Kravtchouk: Growing up in Scandinavia, my design philosophy is rooted in minimalism and trying to find the most simple shape in objects. The biggest influence is from the mid-century and Bauhaus era where our products went from ornamental and decorative to pure function and more emphasis was put on creating a simple form, whether it is a piece of furniture or a motorcycle. In my opinion, that was the most appealing era of design and I wanted to find back to that time in the Tarform bike. Instead of adding more elements, removing everything that is non-essential to find the simplest lines and how they all relate to each other.

When it comes to engineering, the electrical drivetrain is already an elegant solution compared to ICE. It was just a matter of finding the correct placement, and since the actual components are not visual as an engine, they had to take the least amount of visual space. The battery box is just a black box and the motor is a round cylinder, so more emphasis was placed on the body, panels, swingarm and handlebars.

Lastly, the bike had to be connected so the digital user experience had to reflect the design style. We used a round 3.4-inch retina display which gave us complete design freedom over the interaction design. Therefore we could design a custom dashboard from scratch. Every element such as the speed, charge, sound and boot up screen was designed to match the general brand aesthetic. I used ITC Avant Garde gothic for the display as the primary font which was designed by the legendary Herb Lubalin. The icons are simplistic and the color scheme is duo-tone.

Major automotive players and tech companies are grasping for the Holy Grail of integrating AI into the consumer experience. How is Tarform approaching this?

TK: This technology has existed for a couple of years in cars but have not found its way into motorcycles yet. Our first step will be to integrate the production version of the bike with proximity sensors and a Lidar to measure distance to various targets on the road whether it is a pedestrian or a car. Our onboard VCU (vehicle control unit) will process all the data and use a computer vision API to output relevant information on the dashboard. This would be an alert that the vehicle in front of the rider would change lanes without indicating (based on their travel speed) or if the car in front of you will turn right based on their wheel direction.

Simply put, the bike would assist the rider in making those critical decisions much faster than our brain normally would. Another aspect of ML is to track the riders information and at the end of the ride provide statistics and recommendations. A scenario would be to track the rider’s speed going into a corner and then giving them feedback to slow down, based on their history. [This sounds like every pillion passenger ever! - pd'o]

Explain how Tarform plans to offer customization.

TK: During the prototyping stage we realized that the electrical drivetrain offers more flexibility for the exterior design such as the body and side-panels. So we expanded on that idea and designed mounts around all the body work that could easily be swapped out individually without compromising the overall form of the bike. The rider could swap the tank, seat, side-panels, front and rear grill, headlight, fairing, upright bars or clip-ons. Essentially creating a combination of parts to their liking.

What is ‘additive manufacturing,’ and which new biomaterials are you including?

TK: Most exterior parts on the bike were 3D printed using various printers such as FDM, SLS, SLA technology. We worked with EOS (a global leader in additive manufacturing) and created parts such as 3D printed levers out of aluminum, logos and dashboard trims in 3D printed brass. The tank and body panels on the cafe design were printed using SLS in ABS plastic. A lot of internal mounts and headlight lens and lens bucket where 3D printed out of sustainable PLA, which is 100 percent biodegradable. The tank and the side panels where reinforced using ECO flax fiber instead of carbon fiber.

When will American and European customers be taking delivery, and where will the bikes be manufactured?

TK: Pre-orders are open on our website www.tarform.com. Since we are a Swedish company but also based in Brooklyn, the manufacturing and assembly is still under decision and will be announced early 2019.

The Current: Alta Grabs First Electric AMA Pro National Podium

The team at San Francisco-based Alta Motors is most likely nursing a post-celebratory hangover this week after its star rider Ty Tremaine piloted the company’s Redshift EXR to a third-place finish at round three of the Endurocross Championship Series in Reno, Nevada over the weekend, making it the first electric motorcycle to podium in an AMA Pro National race.

Nevada native Tremaine began the day by claiming the second-fastest lap in practice before finishing a close second behind Factory KTM rider and defending series champion Cody Webb in his heat race.

Meet The EXR from Alta Motors on Vimeo.

“The night was almost perfect,” Tremaine said. “After winning the bracket race, the energy of the crowd was amazing. I couldn’t be happier with the way the motorcycle performed.”

After getting a less than favorable start in the main event, Tremaine came around the first turn in sixth position. From there he took the mandated No Joke Lane immediately. The strategy paid off, as Tremaine fell back into the rhythm he had throughout the day, hunting down nearly every rider in the field before finishing third.

Tremaine’s efforts moved him into third place in the series championship points. Will he bump up a step or two on the podium at round four in Denver on October 20? Dorresteyn and his crew believe he can.

The Current: Audi Enters the Electric Age With E-Tron SUV

Audi sold about 1.878 million vehicles globally in 2017, with nearly 227,000 vehicles in the US. The status-symbol manufacturer debuted its first all-electric fast-charging e-tron SUV in San Francisco this week, partnering with Amazon’s Home Services division for home charging stations. The e-tron will come in three models, ranging in price from $74,800 - $86,700, made in Audi’s new Brussels factory in Belgium. Delivery is expected in the middle of 2019.

Audi is aiming at the e-space currently held by Tesla with its Model X, which ranges in price from $79,500 for the 75D version to $140,000 for the P100D. Other luxury brands entering the premium e-SUV market next year are Mercedes-Benz with its $80,000 EQC and Jaguar’s $70,495 I-Pace. My how the times have changed: my first house in Milwaukee, Wisconsin was $76,500 in 1992!

As we reported recently about Audi’s motorcycle brand Ducati, e-bikes are making strides in performance, style and accessibility. So when an automotive juggernaut like Audi goes big with its e-tron, will the two-wheel engineers in Bologna follow suit?

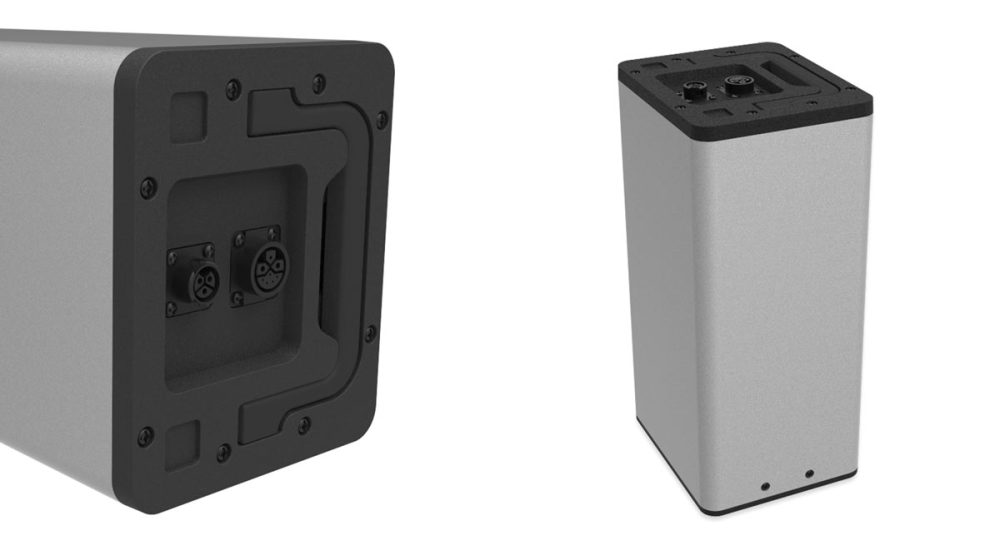

High voltage!

The e-tron’s battery system is located beneath the cabin, measuring 90” L x 63.6” W x 13.4” H. Thirty-six cell modules are housed in shoe-box-sized square aluminum boxes. They are arranged on two levels, known as “floors” – a longer lower floor and a shorter upper one. At market launch, each module is equipped with 12 pouch cells having a flexible outer skin of aluminum-coated polymer. The battery operates with a nominal voltage of 396 volts and stores 95 kWh of energy.

A cooling system of flat aluminum extruded sections – divided uniformly into small chambers – has the task of maintaining the battery’s high-performance operation over the long term. Heat is exchanged between the cells and the cooling system beneath them via a thermally conductive gel pressed beneath each cell module. In what is a particularly resourceful solution, the gel evenly transfers the waste heat to the coolant via the battery housing.

Charge!

The e-tron is engineered for both AC and DC charging via the widespread SAE J1772 and Combined Charging System (CCS) standards. In an industry first to date, the e-tron debuts a DC fast-charging capability of up to 150 kW available at select high-speed public charging stations, this capability can deliver up to an 80 percent charge in only approximately 30 minutes.

For customers’ residential charging needs, a standard 9.6 kW AC capsule charger (Level 2, 240-volt/40 amps) is provided and designed to deliver a fresh charge overnight. This charger will include plugs that can use both a standard 120-volt household outlet (1.2 kW) as well as a fast-speed 240-volt NEMA 14-50 outlet (9.6 kW).

In addition to standard automotive aerodynamics, the e-tron’s standard-equipped heat pump uses the waste heat from the electrical components. Up to 3 kW of the actual power loss is used for cabin heating and air conditioning as well as cooling the electric motor. Depending on ambient temperature, the heat pump’s design can contribute to the Audi e-tron range by up to 10 percent. Highly flexible thermal management also allows fast direct-current charging to help maintain a long battery operating life and repeatable road performance.

Yeah, but what about performance?

Two electric motors accelerate the e-tron from 0-60 mph in 5.5 seconds, reaching a top speed of 124 mph. Maximum drive torque is reached in 250 milliseconds! God bless electronic drivetrains. Two asynchronous motors are designed to keep the temperature level low. Single-stage transmissions transfer the torque to the axles via the differentials, and each motor is supplied by power electronics that act in close consort with the powertrain control unit.

According to Audi, when the e-tron is traveling at moderate speeds, it’s powered mainly by the rear motor. When coasting, the motors operate free from magnetic drag torque – another strength of ASM technology. The e-tron uses an innovative recuperation system using both electric motors to boost efficiency. On average, Audi engineers estimate that this system is responsible for as much as 30 percent of the e-tron’s range depending on the conditions, terrain and driving style.

The electric SUV can recover energy in two ways: by means of coasting recuperation when the driver releases the accelerator, or by means of braking recuperation by depressing the brake pedal. When pressing the brake pedal, the electronic control unit computes within milliseconds how much pressure the system needs to build up for the specific braking process required. A high-performance electric motor supplies the necessary energy. The integrated brake control system is approximately 30 percent lighter than a conventional system thanks to its more compact design. As a result, the conventional vacuum pump is no longer needed in this configuration.

Additionally, the brake control system decides whether to use the electric motors as alternators or to use the friction brakes – all without the driver noticing. Up to 0.3 g, the Audi e-tron is decelerated solely by the electric motors – that covers over 90 percent of braking scenarios. So energy is returned to the battery in practically all normal braking instances. Above this deceleration value, for example in a full brake application, the friction brakes come into play. Thanks to a newly-designed, electro-hydraulic activation principle, they are particularly quick to respond. The driver can select the degree of energy recovery in three stages by means of paddles on the steering wheel. In the lowest setting, the Audi e-tron glides with no additional braking torque. At the highest stage the electric SUV is slowed more noticeably – the driver can slow down and accelerate solely via the acceleration pedal, if desired. This creates what is referred to as a `one-pedal’ feeling.

The efficiency assist additionally promotes an economical driving style by prompting the driver when he should move his foot off of the accelerator pedal. It does this by using the navigation system’s route data, radar information and camera images, Depending on the traffic situation the predictive system makes the Audi e-tron slow down proactively and in turn, recuperate.

Amazon partnership

Audi e-tron buyers can ready their homes with available Amazon Home Services in the first-ever home charging collaboration between Amazon and an automaker. “Audi Home Charging powered by Amazon Home Services” offers e-tron buyers a fully-digital experience for in-home electric vehicle charging installations, designed to make the process of home charging setup as easy as ordering other items from Amazon. [Audi]

Of course there’s an app

The myAudi app can be used to plan, control, and monitor the charging and pre-heating/-cooling of the e-tron. Customers can set a departure time, for example, so that the vehicle is charged and/or heated/cooled at the desired time. Customers can even choose to heat or cool certain zones in the car. On cold winter days, for example, customers can turn on the optional seat heating. The app also displays charging and driving data.

Amazon’s voice-activated ‘Alexa’ software has been fully integrated into the e-tron’s MMI system and is on board for customers to access many of the same features and services in the vehicle as they can in their home or through other Alexa-enabled devices. You can check news, weather and sports scores, order groceries and add things to your to-do list, stream music and audiobooks via Audible, Amazon Music and TuneIn. With smart home controls, you can lock the doors, turn off the lights, and close the garage door directly from the vehicle – all you have to do is ask.

Audi e-tron customers are now able to configure and reserve their vehicle with a fully refundable $1,000 reservation fee ahead of delivery in mid 2019. Audi’s 303 US dealers provide a much wider ecosystem compared to Tesla, and coupled with Mercedes and Jaguar entering the premium all-electric SUV arena, it will be interesting to see how Elon Musk handles the newly-crowded space.

The Current: Would Ducati Build This Electric Motorcycle?

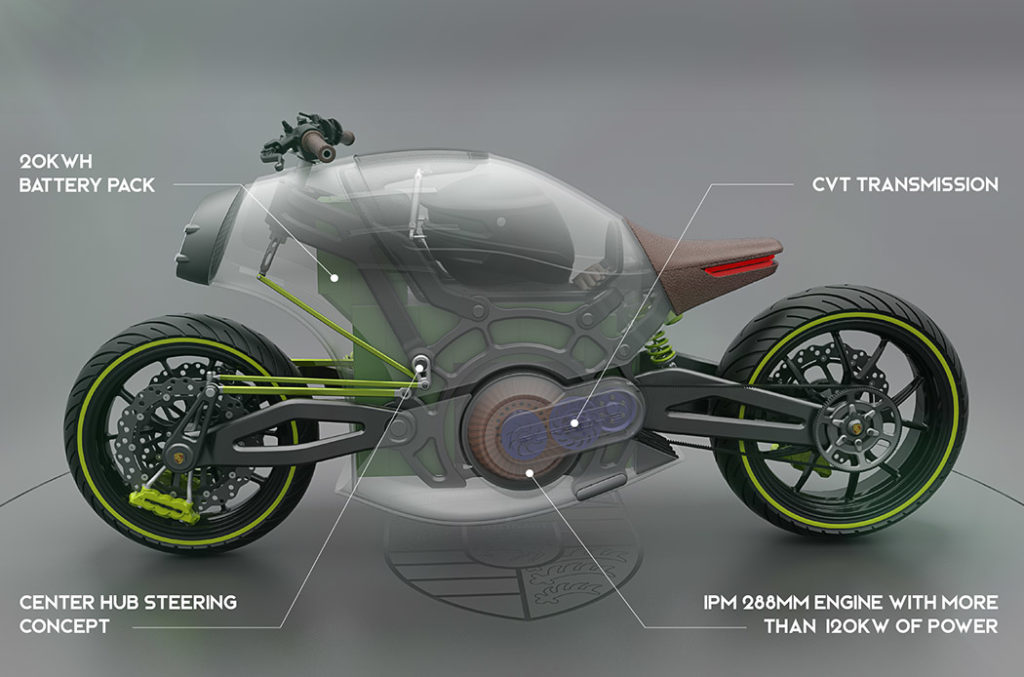

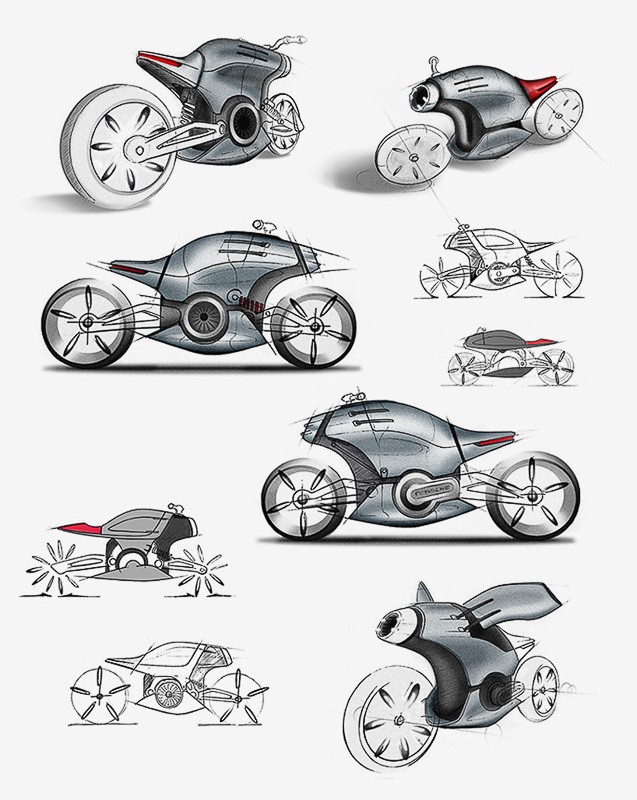

Spanish designer Miguel Angel Bahri imagined a Porsche-inspired electric motorcycle concept last year, basing his vision on the iconic German automaker’s masterful 911 series and its evolved lineage. He called his concept the ‘Porsche 618’ - it was highly detailed, and looked like a realistic option for production.

“Inspired by the Flat-Six engine, the inspiration came to my mind in the way of thinking in a low center of gravity. Center-hub steering was a key element to get the right balance between design surfaces and mechanical features, allowing me to put heavy visual parts such as the direction components, front and rear arms and even springs configurations below the middle of the motorcycle.”

“After this, the idea was how to relate a sporty silhouette feeling, typical from Porsche, without losing lightness of the body, this because as a real power cruiser motorcycle, it should have a good range/performance ratio and the +20 KwH battery has a prominent volume to take into consideration.”

Bahri's concept seeks to extend Lamborghini/Audi/Volkswagen's ownership of Ducati into a new direction: they're owned by an automotive juggernaut, is his design the mental springboard Ducati's engineers need to hop on the electric motorcycle train? Ducati is hedging its bets regarding plans for e-bike development, while Harley-Davidson has aggressively moved forward, announcing the opening of a Silicon Valley-based engineering outpost to focus exclusively on electric vehicle development in Ducati North America’s own backyard.

Bahri is no conceptual design slouch. He was part of a five-person team to collaborate on a Tesla T1 LeMans 2030 concept for his IED Barcelona transportation design class, a reflection of the e-chops he introduced to the world with his Porsche 618 in early 2017.

“Color combinations were a key feature to reduce visual weight from the main body,” Bahri said. “With this I could make body partitions but also I put some elements into perspective to gain more importance on top of others.”

“In the final design, the two main liquid metal silver surfaces make the impression of ‘floating’, as the battery CFRP case serves as a background for this element, taking advantage of its darker-matte color to reduce visual weight,” he added. “The futuristic details such as the headlights, taillights and the trunk aperture system complete the (overall) design of the 618.”

Maybe Bahri could arrange to have an espresso in Milan with Ducati designers to discuss motorcycles?

The Current: From Russia, With E-Love

The name Kalashnikov immediately conjures up the Russian-made AK-47 assault rifle, still in production since its inception in 1949. Seventy-five million have been produced, making it the most popular armament in history, and the company bearing designer Mikhail Kalashnikov’s name has been diversifying into electric vehicles lately. Arms manufacturers care about the climate too, you know!

Over the past year, the Kalashnikov Concern has introduced a handful of electric military and consumer motorcycles, a “flying car” which looks more like a rudimentary motorcycle drone that the Green Goblin would love to pester Spider-Man with, and a small car to gobble up Moscow miles. As with most e-concepts and limited production runs popping up on the interwebs, specs are minimal and pricing is non-existent, just like a good cup of coffee at the Kremlin.

SM-1

Top speed is 56 mph with a range of 93 miles, relying on a water-cooled brushless motor and lithium-ion battery and 15 kW/h of energy. Telescopic inverted front fork and hydraulic central spring shock absorber handle suspension. Length is 86.6 inches, height is 51.2 inches and wheelbase is 59.1 inches. If Kalashnikov design practice is expected, the SM-1 and its variants will be simply constructed, relatively light, and fairly indestructible. The trellis tube frame protects the batteries from side/fall impact, and gives a neat, angular geometry to the bike.

UM-1

This Urban Moto is designed for the adventurous люди and женщины, relying on 15 kW/h of electricity. Top speed is 62 mph with a range of 93 miles like the SM-1, relying on a water-cooled brushless motor and lithium iron phosphate batteries. It weighs 364 pounds. With a relatively short range, SM-1 adventure riding will strictly be limited to Moscow traffic, but urban riders will win big style points.

Pulsar

The Department of Transport and Development of Road Infrastructure of Moscow used 30 of these during the recent Football World Cup. Like the SM-1 and UM-1, it also relies on 15 kW/h of energy and a brushless DC motor. Top speed is 62 mph with a range of 93 miles, and in accordance with the UN Economic Commission for Europe Regulation No. 41, the noise level is below the maximum requirements and is less than 75 decibels.

Motodrone

All this mislabeling of `flying cars’ needs to stop! Let’s call this one a motodrone, because the pilot is seated in a motorcyclist’s position, relying on eights pairs of rotors that provide lift. Where it deviates from a land-locked motorcycle is in its skeletal metal frame and joystick controls.

Two banks of what appear to be batteries are located under the rider and likely provide electricity to the rotors. A chassis or shell is shown superimposed over the motodrone at the end.

Drones and electric vehicles are popular, and the marriage of the two for personal transportation aircraft is admirable. With the right vision and execution, a flying motorcycle could be filling our friendly skies before we know it. But who will win this new technology race, Russia or its nemesis the United States? More importantly, when will we see motordrone racing?

CV-1

Referred to as a “supercar” concept, the CV1 will strike a chord with any former Soviet citizen, as it riffs on the FIAT sedan built under license in the Soviet Bloc as the Lada - the best car an average person could buy, after a multi-year waiting period. The CV-1 has rallycar/bad guy appeal, with a short wheelbase, big wheels, and blacked out windows: the perfect getaway vehicle. It has a claimed power of 220kW, with a range of 218 miles, or much less when drifting sideways after a bank heist (or an assassination in a London park).

Ovum

The 1,102-pound Ovum electric car concept has a top speed of a mere 50 mph and a range of 93 miles; maybe KC needs to reconsider what to put under the hood, because all it did was reportedly drop in a similar 15 kW/h brushless DC motor as the e-bikes mentioned above.

But take heart! The Ovum ”has a high smooth running and low fire and explosion hazard in the event of an accident,” according to Kalashnikov...who know all about fires and explosions.

The Current: Here Comes Vespa's Elettrica e-Scooter!

The 2018 Vespa Sei Giorni 300 scooter retails for $7,699, and if the fuzzy logic of parent company Piaggio is any indication, its long-awaited Elettrica electric scooter will arrive in the US sometime in 2019 for roughly the same price. Is anybody gonna bite on an electric Vespa with the same amount of range and gusto as a 50cc for a 300cc price? While the love the concept of an electric Vespa, our money’s on the next-gen Elettrica X hybrid, coming out soon.

The Elettrica—to be produced at the Pontedera plant in the province of Pisa, the same one where Vespa first rolled off the line in the spring of 1946—is silent, and has some artificial intelligence features, including nearby pedestrian and vehicle detection, along with suggesting alternative routes when traffic is bad. With something like 200+ Million e-scooters already on the road in China, proof of concept is already here, and electric App-scooters are very popular in San Francisco (Scoot), so demand is already there in the West as well. The Vespa name and style is iconic and carries a seemingly eternal brand weight, so an electric scooter seems a likely success.

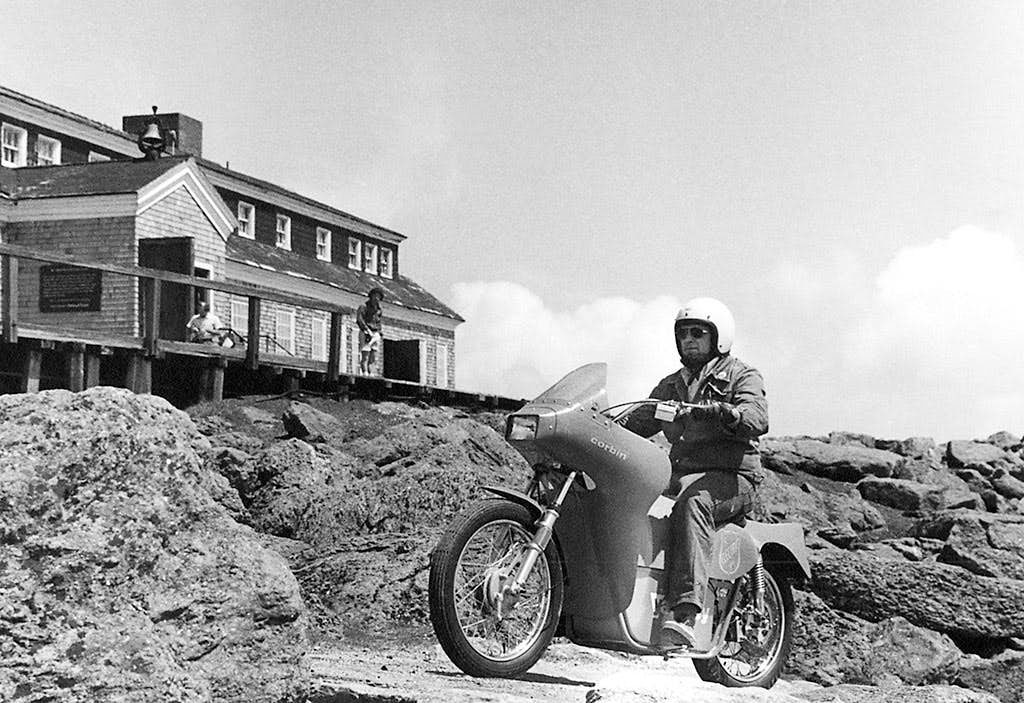

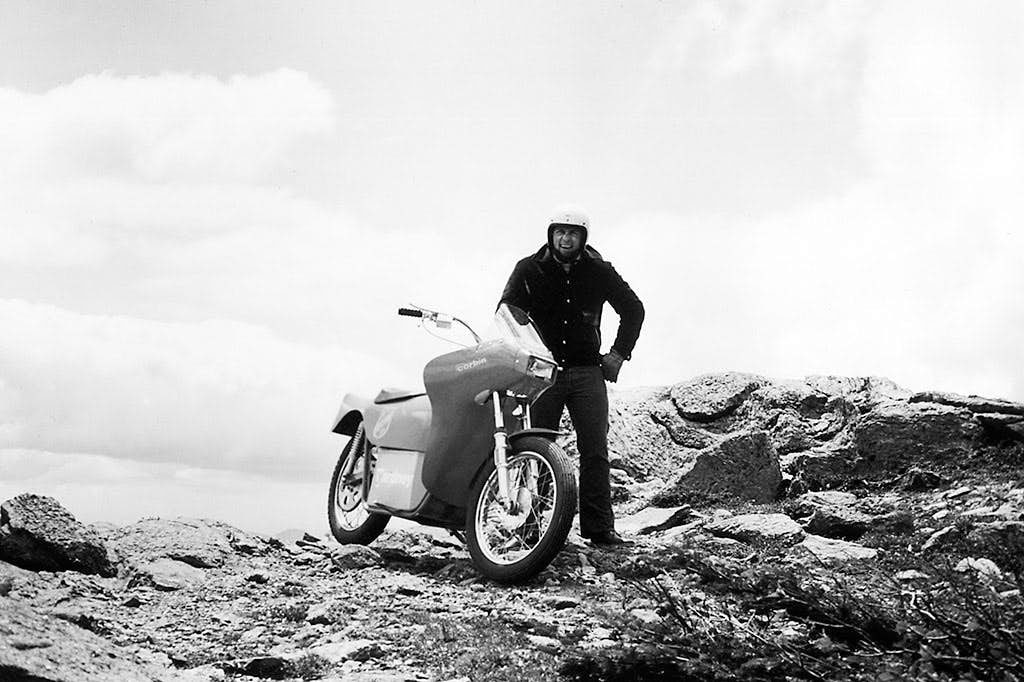

The Current: Mike Corbin, E-Bike Pioneer

In 1967, Union Carbide employee Karl Kordesch made a fuel cell using nickel–cadmium —later replaced with a hydrazine fuel cell— and created a hybrid electric motorcycle with a range of 200 miles and a top speed of 25 mph. Serial innovator Floyd Clymer built the Papoose prototype electric Indian bike the same year. Six years later Mike Corbin took it one step further.

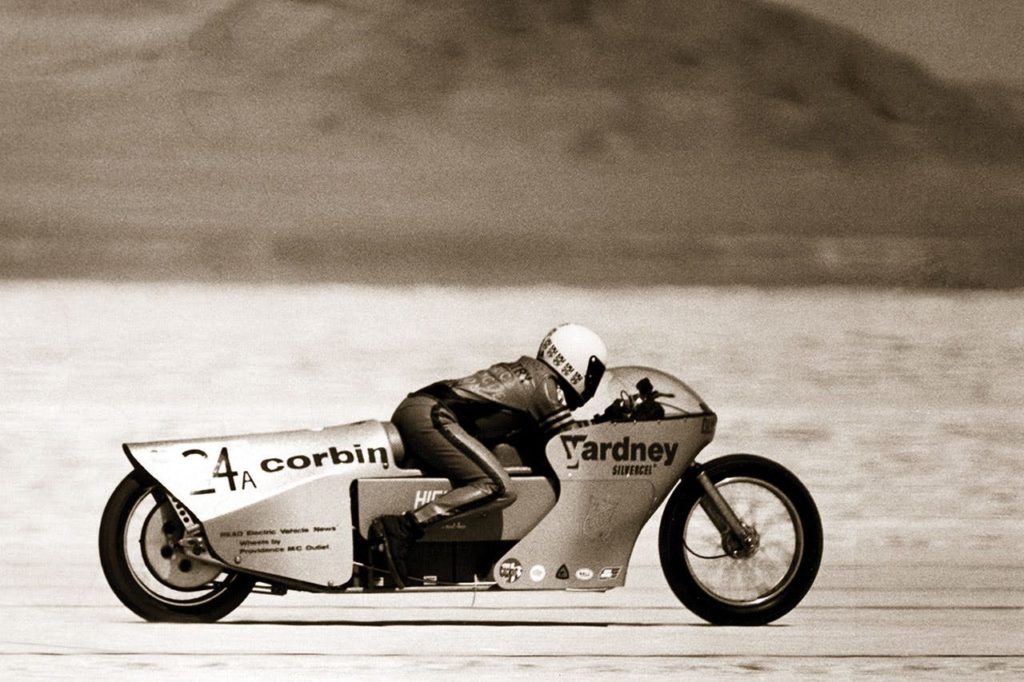

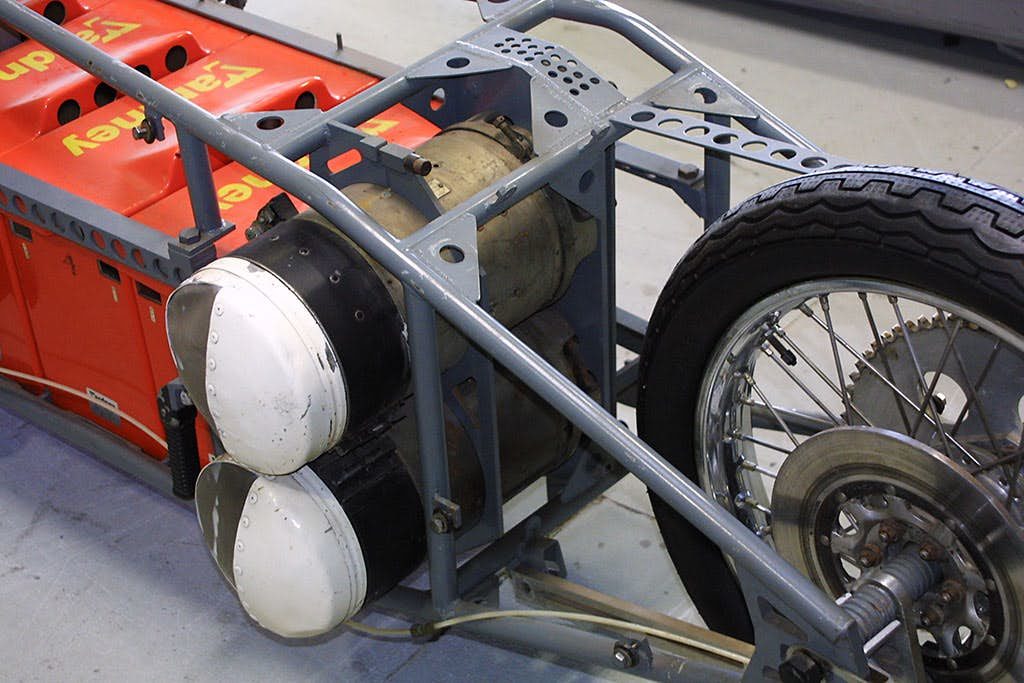

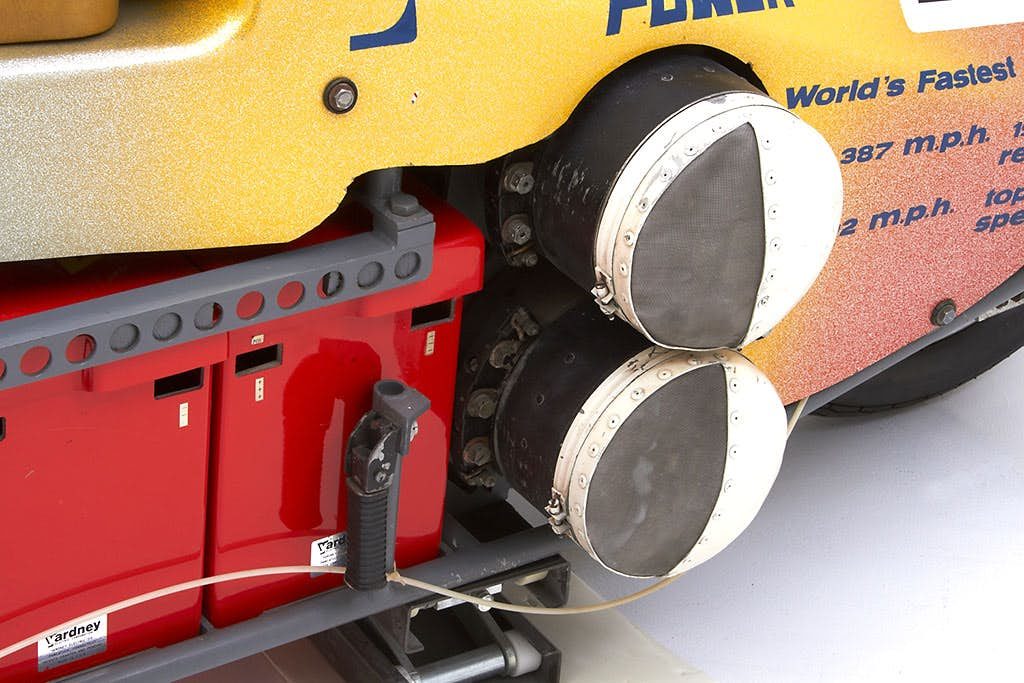

Popular motorcycle custom seat maker Corbin is based in Hollister, California, about 100 miles south of San Francisco. The company celebrated its 50th anniversary recently, and few newer riders are likely to know about company founder Mike Corbin’s significant role in electric motorcycle development in the 1970s. His experiments with electric motorcycles range from an electric minibike, to an electric street bike with production intentions, to an electric land speed bike, which set a record of 161.387 mph round trip, with trap speeds over 201 mph at the Bonneville Speedway in Wendover, Utah in 1974. The record stood for 38 years until the Lightning LS-218 surpassed it in 2012. Later, he attempted to mass-produce an electric personal mobility vehicle, the Sparrow, and received $40Million in orders!

“When Lightning came along, they had the battery chemistry down. Plus, what you have now are the AC controllers, those and the AC motors are just unbelievable. You have such amazing equipment now that it's almost unlimited what we're going to be able to do with electric vehicles.

“But in those days, it had to be DC if it wasn't gonna have a wire on it. DC electricity itself limits you a great deal. Everything's heavier and high amperage. So the A4B DC starter motors; we bought a full pallet of them from the Navy surplus, because they used to burn up. You'd get going like hell, and they'd overheat and solder would come out of the commutators. And these copper bars would fly out into the motor, and you'd have to throw the whole thing away. So I had a bunch of those, I think I've still got some out in my warehouse.

“So it'd start at 12 volts, then you'd switch to 24 volts, then you'd go to 120. If you put the 120 volts on immediately, the wheel would just spin and dig a hole right in the salt. So we had a flying start, we'd tow the bike up to anywhere between 40 and 60 mph with a car, then I had an ejection rope, you'd spring load this thing and it'd fall in the salt, and I'd go around the car and start accelerating."

“There was this guy, his name was Dr. Petrocelli, he was a naval engineer. He'd been a big shot in the Navy and he was the CEO out at Yardney Electric, who made those batteries for the nuclear subs. I got along great with him, because I'd been an electrician in the Navy. So he says "well, it's $100,000 for the battery." And I said "well I don't have no hundred thousand dollars for a battery." He says "well, it's really worth it, because there's a hundred thousand dollars worth of silver in it." And I go "well yeah, I understand that, but I don't have a hundred thousand dollars for a battery. You're the sponsor, that's your problem."

So we need 220 volts AC for the battery charger. I get my wife on the phone with this little hotel in Wendover, Utah—that's near where Bonneville is. I says "Okay, Jane, don't let the cat out of the bag. Call them up, make sure they have a washer and a dryer." And I'm visualizing that I'm gonna have 220 with 30 amps, at least.”“She calls them up and they say 'don't worry, we've got a full laundry.' So I'm telling the Yardney guys "yeah, we're gonna charge the battery off their 220 volt dryer socket." But we get there and what have they got? A 110 volt dryer. Seriously, you couldn't dry two handkerchiefs in that thing. So now we've got no 220 plug.

“Well, we needed 220 volts, and there's only one place we could get it! I'm looking up at the power pole… I used to work as an electrician, wiring houses out in Connecticut. So I knew exactly what I was looking at. But we didn't have any wire! I mean you can't go up there with a lamp wire, it's not big enough. But jumper cables…

But it did the job!

“Yeah, we had a lot of fun,” Corbin said. “And that's how we did the first motorcycle land speed record!”

The Current: Motochimp Is The Ultimate e-Pit Bike

Singapore-based Go Go Machines has slotted itself into the cool-kids corner with its Motochimp electric pit bike. Who among us wouldn’t want a forward-looking pit bike to jet around El Mirage, Bonneville, Wheels & Waves, Circuit of the Americas or Laguna Seca? The Motochimp clearly plays on the 'monkey bike' theme, the pit bikes made by Honda in the 1960s, little bikes that fetch big money today, as well at the Motocompo folding bike built for the Honda City, that's become an icon of 1980s design [see our article on top '80s design here].

The Motochimp is made of stainless steel and aluminum alloy, and is compact like a proper pit bike needs to be: 43.4” (L) x 25.8” (W) x 45.4” (H), with a 29.6-inch wheelbase.

“Over the last several years we have invested heavily in the development of new battery technology and the development of electric transportation solutions to address two key consumer concerns: firstly the issue of battery and vehicle range and secondly the speed of re-charging,” CEO Larissa Tan said. “With our fast charging, energy dense lithium-titanate batteries, we’re already solving those issues.”

Parent company Vanda Electrics also builds an electric light commercial vehicle called the Ant Truck and the Dendrobium D-1 concept electric concept supercar.