The Current: Harley-Davidson Going E-Big in 2019 and Beyond

On a recent tour of the 10-year-old Harley-Davidson Museum in downtown Milwaukee, Wisconsin, I was reminded of the Motor Company’s legacy with displays of bicycles, lightweight motorcycles, and advanced projects dating back nearly 115 years. This was just a few hours after H-D announced several concept models to address the burgeoning need of electrified transportation, including its LiveWire for 2019, a whippy-fun street tracker, two bicycles, and an electrified and modern update on the old H-D Topper scooter. The release of new models is planned through 2022, and it's clear the company is banking their future existence on this new lineup.

The Current: Are Tilting Electric Vehicles The Future?

Jean-Pierre Peugeot and Jean-Frédéric Peugeot established their eponymous French company in 1810. By 1842, they produced coffee, pepper, and salt grinders. The company's entry into the vehicle market was via crinoline dresses (a stiffened or structured petticoat designed to hold out a woman's skirt, popular at various times since the mid-19th century), which used steel rods, leading to umbrella frames, saw blades, chisels, wire wheels, and bicycles. Armand Peugeot introduced his "Le Grand Bi" penny-farthing in 1882; seven years later he built his first automobile.

With a primary focus on city use, the vehicle’s small footprint (nearly eight foot long by a little more than two-and-a-half feet wide) and rotating doors free up road space and make for quick and easy parallel parking. [Groupe PSA]

With all this momentum, Peugeot has invested its resources into future mobility solutions, based on a plug-in hybrid electric vehicle (PHEV) with tilting wheels and a tandem passenger design; let’s call it the e-Tilt. Based on architecture similar to a tricycle, Peugeot’s electrified light vehicle is adapted for urban and short trips with a zero-emission mode for city driving.

Funded with 6.7 million euros from the European Commission under the “Horizon 2020 GV5” Research and Innovation program, the e-Tilt is part of the “Efficient Urban LIght Vehicle” (EU-LIVE) European consortium, bringing together 12 partners from six countries, with Groupe PSA the only carmaker. One of the EU-LIVE consortium’s main objectives is to develop common powertrains that can be used for a variety of L-category vehicles to achieve economies of scale.

The e-Tilt runs in zero-emission mode at speeds up to 44 mph using two rear electric in-wheel motors, developed by Elaphe and Brembo.The 48-volt electric battery—designed by Samsung SDI—can be recharged using regenerative braking technology. When driving between 44 and 80 mph, the e-Tilt’s 31-KW single-cylinder gas engine takes over. The light vehicle has a total range of 186 miles and a top speed of 80 mph.

“Groupe PSA has committed to protecting individual freedom of movement,” Peugeot’s Senior VP of Research and Advanced Engineering Carla Gohin said. “EU-LIVE is an illustrative example of it. This new electrified light vehicle allows an individual safe and sustainable mobility thanks to its zero-emission mode. We are proud to take part in this European project with all our partners.”

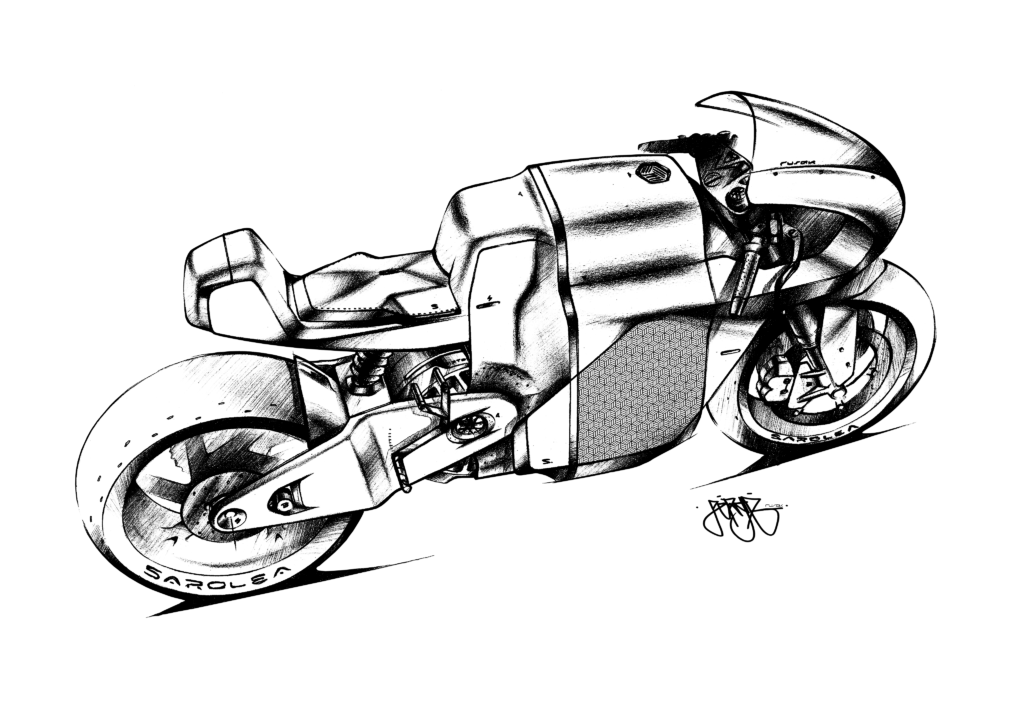

The Current: Saroléa Introduces Limited Edition MANX7

One year ago, Torsten Robbens was excited. His company, Saroléa Motorcycles, was one of only four vying for Dorna’s attention to become the spec motorcycle for its Moto-e World Cup in 2019. That honor went to Energica, but the Belgian company soldiered on, focusing its attention on a limited-edition street-legal bike, the MANX7, based on its Isle of Man TT creation, the SP7.

Due to this configuration and the nature of the fully stressed structure, the MANX7 was designed with a 50 percent front and 50 percent rear weight distribution, which Saroléa says gives it great handling and makes it easy to ride. The weight is 478 lbs (217 kg), including a 22 kWh battery pack.

Only 350 MANX7 bikes will be made. Excluding tax, clients can choose from 14 kWh for €42,975, 18 kWh for €46,280, or 22 kWh for €48,760. A €5,000 deposit is required, which is fully refundable if you cancel your reservation.

In 2017, Saroléa achieved its fourth Isle of Man TT in a row with its SP7 race machine and onboard their development rider and emerging champion, Dean Harrison. Another prize (Lady bronze) to add to the previous trophies obtained over four years of development and competition on the Isle of Man. The extreme conditions and very specific set-up required to complete in the IOM TT race offers Saroléa a unique development platform in terms of performance and safety.

This challenging event enables Saroléa R&D to gather huge amounts of data which it turns into enhanced solutions for its street-legal motorcycles. I spoke with Robbens on a busy July evening recently to learn more about the MANX7.

Torsten, how long has this MANX7 been in development?

The MANX7 is derived from our TT Zero racing bike, the Saroléa Project 7 (SP7), which began in 2009. Racing the SP7 itself started when we joined the Isle of Man TT Zero in 2014, and we envisioned the TT Zero to go international, or at least another international racing championship to kick off around then. That’s why we always focused on our racing bikes.

Our idea was, and still is, to sell and lease out the SP7 bikes for these championships to other teams. As we saw no real evolution toward a global championship we decided to start the development of road-legal motorcycles in 2016. This would become the Saroléa MANX7.

It’s a difficult question to answer; as we are driven by passion we don’t exactly keep track of every hour we spend in the workshop (laughs)! Our team is now 20 people, which doubled over the last two years. In total we’ve now spent nine years in research and development, racing, trying, failing, learning and evolving.

How did you choose your parts and component partners?

Most of the MANX7 special parts come from our racing activities and development, and it’s quite logical to use the same manufacturers and parts. Or at least variants of these parts in a road legal version. We’re always looking for the best quality and lightweight for our machines.

The partners we work with have the same spirit and drive. They’re looking for perfection in performance and aesthetics. Plus they are also very agile in the way they communicate and operate. This is absolutely necessary for a small company like ours.

As a side note, all of the carbon parts, including chassis, swingarm and bodywork, but also the production of the motors and battery packs are done in house.

This year we’re building the first 20 bikes, the founders edition. The following years we’ll increase the production: for 2019 we have a production run of 80 bikes, and in 2020 we will produce 250 MANX7 motorcycles.

That is the absolute maximum number of bikes to be produced per year; delivery of the first bikes is scheduled for Q3 and Q4 2018.

Have you established a North American distributor?

We have received quite some interest from different North American distributors. We are actively talking to an exclusive vehicles (cars and bikes) distributor in New York City and a couple of potential resellers in California.

The Current: Exclusive Interview With Zero CEO Sam Paschel

With an engineering degree from Swarthmore College and a competition background as a decathlete, Sam Paschel was an ideal candidate to take the reins at Zero Motorcycles in Scotts Valley, California in February 2017. The 43-year-old learned how to develop product lines and lead teams during tenures at Bell Sports, Burton Snowboards and Skullcandy. But with motorcycling running through his veins, it was inevitable that he would be involved with motorized two wheelers eventually. We shared a ride and lunch with the Pittsburgh, Pennsylvania native recently, touching on several facets of his career and future plans for Zero Motorcycles.

I’ve been riding motorcycles since I was 8 years old. I had a Suzuki RM80 for a couple of years that was a surprise gift at Easter. I laid it down in some gravel at my uncle’s farm and it somehow disappeared out of the garage. Maybe it was revenge for my parents taking away that bike?

I’ve been fortunate enough to work in different fields during my career, from bicycle and snowboard to the audio side, talking to a very similar consumer. I’m passionate about motorcycles, and a lot of it with Zero was opportunity based. Running businesses successfully is choosing the right space at the right time, so beyond being a rider I looked at the tipping point for two- and four-wheeled electric vehicles, where the technology has evolved to, and there’s this feeling of inevitability with electrification.

I quickly understood four things were needed to successfully lead Zero: one, I had to believe in electric vehicles growing as a percentage of transportation; two, that motorcycles will become a part of that transition, not as quickly as cars, but as part of the infrastructure as technology improves; three, that as battery technology improves eight to 10 percent each year, we get this tailwind of range, power and performance just from improvements in lithium ion technology, not from any major breakthroughs.

At the same time, because the standard internal combustion engine motorcycle is a pretty dirty vehicle that pollutes, emission controls are being rolled out around the world that increases costs and decreases power. I understood all these things intellectually, but after a couple months talking to recruiters and Zero’s investors, I took a 50-mile ride on my Triumph Bonneville and took my first ride on a Zero. I went from being curious to desperately wanting to be a part of what was being built at Zero. Twenty minutes on that Zero was all it took for me to want the job.

The ultimate success would come if they would make a change in the federal tax credit to be a forward versus retroactive one. What they put into place was a tax break for a past purchase, not an incentive for someone to make a new purchase. With everything going on in Washington, with the tariffs and corporate tax breaks, it was a good opportunity for Zero to take a leadership position on behalf of several two- and three-wheeled electric manufacturers to testify on their behalf. But the proof is in the pudding; the government has kicked the can down the road a bit and nothing has changed yet. The good news is that we’re still on the docket as a special case, with discussion of something happening in October or November. We gave our written testimony and I had the chance to sit in front of the Subcommittee on Ways and Means and let a voice be heard for our industry, which was really cool. It was a fantastic experience for me personally, and it continues to represent Zero’s position at the highest level.

We’ve been engaged with legislative bodies for a very long time, lobbying on behalf of electrification. The capital is like the world’s biggest home court advantage; they sit on an elevated dais; you get three to four minutes to give your testimony, with 15 minutes per cross examination. There’s C-Span, a countdown timer staring you in the face, Congressmen and women wearing makeup; it’s crazy! I walked in understanding that all those people work for me. One can’t be extemporaneous in three minutes, so you drill down the facts and hope for the best. But I could think on my feet during the cross examination because I knew more about my business than anyone else in that room. I was there to share and educate. You’re expecting it to be adversarial, but it’s not. It was a chance to make a case for two- and three-wheeled electrification.

Zero has a history of competition, including Pikes Peak and Bonneville Speed Week. In your opinion, does racing help the breed and sell more bikes? Flat track seems to be a viable option for Zero...

Organized racing programs require a large investment. The beating heart of the subculture at Zero is competition, actually. The passion points include track days for many of our engineers and employees, and MotoGP is playing on multiple screens several weeks out of the year. Helmets are on 80 percent of our desks in the office.

But an organized racing endeavor would be a massive investment. That same investment is better spent educating our dealers and consumers to grow the business. At the same time, competition is a very natural passion point for the employees, so we do everything we can to provide bikes, leathers and time off to pursue that.

It has the chance to. The Formula 1 electric category has been around for awhile, but that’s not what expanded broad acceptance. Anytime electric motorcycles are out there as part of the conscious experience for people, every single one of those touch points helps gain awareness that the electric category exists. You want an exciting race that goes a reasonable number of laps at speed, and that’s not an easy thing to accomplish with an electric production motorcycle. Those steps and moves continue to put electric motorcycles in the collective consciousness, and on balance that’s a good thing.

Which Zero model do you ride and enjoy the most?

I own a Zero FX, our enduro model. With two young kids I don’t go on long rides; it’s a 7.2 kilowatt-capacity bike with an in-town range of 85 miles, on the highway about 50. Most often I’ll get up early on a Saturday and rip down Highway 1 to Davenport ad get a coffee, ride across town to work. It has a relatively tall riding position with a narrow profile, ideal for lane splitting. Ton of visibility. In a town like Santa Cruz where I’m using it every day, I can cut across the railroad tracks to connect to a dirt road. My ultimate west side/east side Santa Cruz vehicle. If need be I’ll hop on Highway 17 to get to the office quicker.

Fleet sales have always seemed like a smart business move for motorcycle makers. What percentage of Zero’s sales comes from military and police?

Less than 10 percent for us today. We have 100 authorized dealers in North America and 100 in Europe, but very few fleets will transfer completely to electric. It’s more likely they’ll have one or two bikes for local patrolling, but not for pursuit. Electric’s range and high speed capabilities aren’t there yet. The cross section where we’re casting our net into comes in orders of fives and tens, not hundreds or thousands. The process to get funding, as the administration shifted in the US, is now totally economic: cost of ownership, maintenance, etc. Total cost of ownership of an electric motorcycles is much less than internal combustion: no oil, no air filters, mufflers, etc. So when you pencil out purchasing price versus long term ownership, the controller for a city or town can justify the purchase. Plus there are eco reasons depending on the political leanings. Grant proposals need to be worked through.

Military purchases, on the other hand, take years of cultivating relationships but tend to lead to much larger orders. I can’t talk much about it yet, but we’ve been engaged in these conversations for a very long time in the US and abroad for the military application of our bikes. Incredibly quiet, very low thermal signature. In the case of an emergency crisis situation, the first thing that gets turned back on is the power grid. Even if you can’t get fuel from place to place the power lines are up, giving electric bikes the advantage.

Your competitive landscape is about to get more crowded. We heard the news about Harley jumping into the electric motorcycle space sometime in 2019, and it’s only a matter of time before Polaris unveils something. How is Zero scaling up to meet the demand, and which rider segments have the most potential?

When Harley first announced its LiveWire in 2014, traffic to our website spiked to record levels, just like it does every time a company announces e-bike intentions. Other brands coming into the party is something that we welcome. A rising tide lifts all ships, and we’ve had 12 years and millions of miles to perfect how our powertrain functions; these are non-trivial problems to solve. As you see other entries this will be the starting pistol to a different kind of competition. The number number of manufacturers will go up and the number of bikes produced will increase. But all of the work it takes to create a dealer base that’s knowledgeable at selling and good at explaining this technology, plus servicing the bikes is huge. The big manufacturers will have a dealer base to start with, but any incumbent internal combustion engine company is going to be competing with itself if it just poured electric bikes into its existing distribution points they’re going to end up with a lot of unhappy customers. They’re not going to understand how to articulate the benefits of electric right away.

The learning curve on preparing dealers is high. Zero is a market leader, testifying in front of Congress. The more human beings riding electric motorcycles place to place, the better the world will be. Zero will earn its fair share of business regardless. Technology places well in certain categories; we have a broad model offering and a solid, collaborative dealer base.

We have 150 worldwide employees and a new distribution model. We scaled back our underperforming dealers, and now stand at 100 North American and 100 European dealers, sold in 30 countries worldwide through distributors.

Where do you hope to steer Zero over the next five years?

There are some near-term things 18 months into my tenure, one of which is continuing to cultivate strong relationships with our dealers, and look at other ways this consumer journey is happening to go from an awareness that electric motorcycles even exist to purchase. The next two to three years will be spent increasing our leadership position and investing in battery technology and powertrains are critical. The biggest shifts will include how we articulate our story with consumers and invite new riders using electric as a lever.

Back to your first question about why I considered running Zero: I looked at a product that was so fundamentally different than 95 percent of the market, and this idea that ‘may the best motorcycle or car win’ is not how this works. We’re not competing to win, we’re competing to differentiate, through marketing, product, what have you. What I saw was a refined function on an advanced technology down to the very base DNA, and none of what we did with our marketing or storytelling lived up to the function of what we had created as a product.

Look at Nike; billions of athlete endorsements and marketing to basically tell you its cotton t-shirt is fundamentally different than its competitors.

This business had already figured out solutions to challenging technological questions, but we hadn’t figured out how to tell the story.

Our job is to articulate the story of Zero, which unlike a cotton t-shirt, is completely different at the very base of what it is. We need to let the brand breathe.

In five years our attraction to potential customers will shift from tinkerers to late adopters to our technology. Different products and stories will resonate with them, but you can count on Zero to maintain its leadership position among all motorcyclists. We’ll continue to tell our story and get our technology into the hands of the consumer so they can have a great experience.

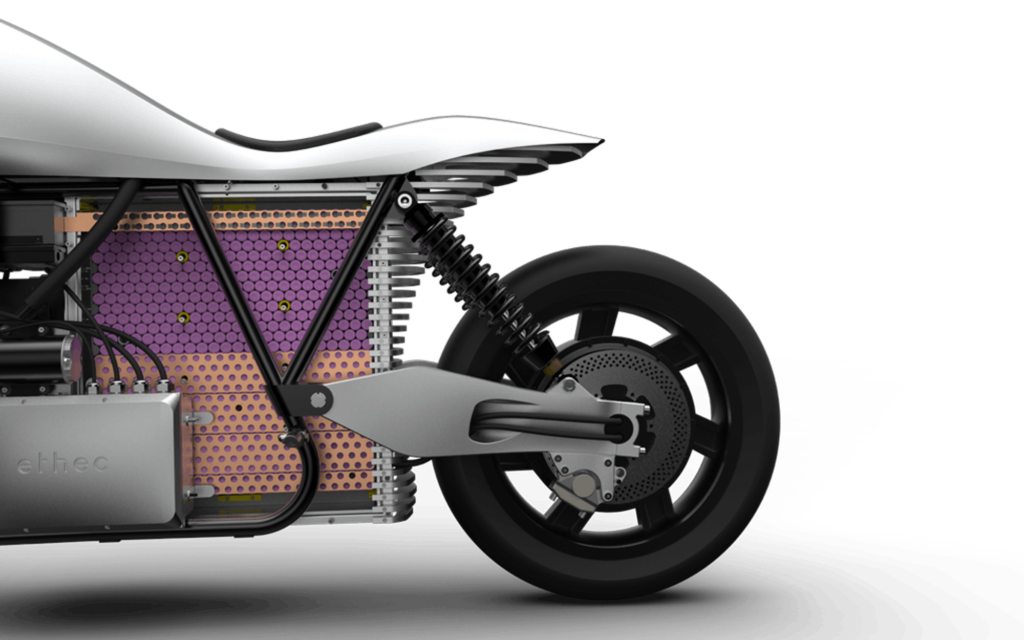

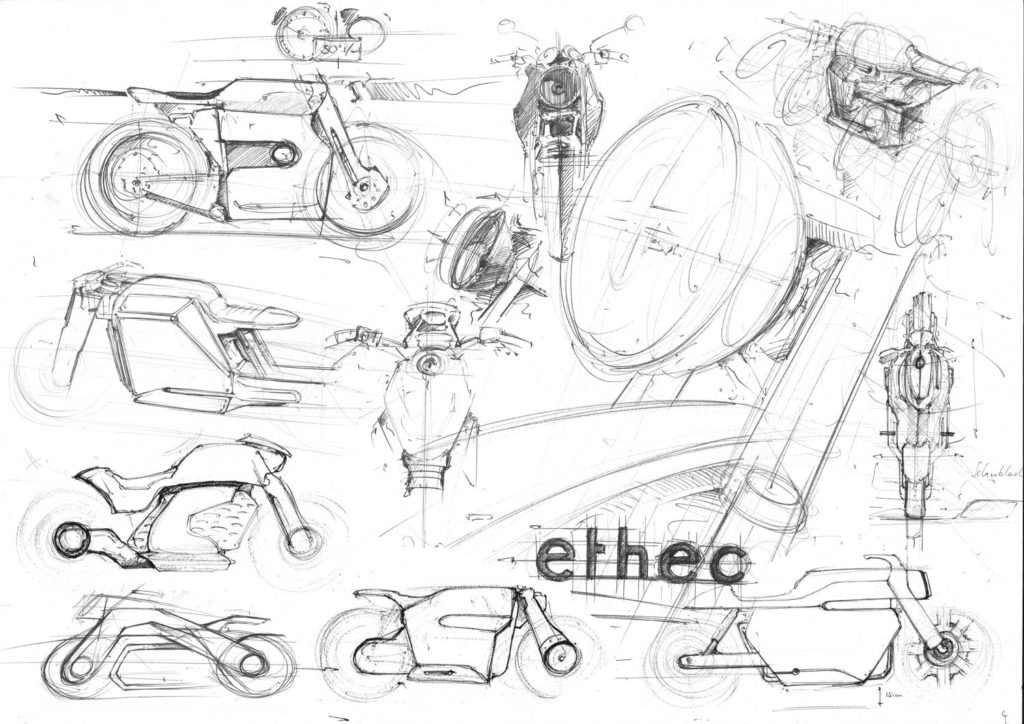

The Current: Ethec’s 250-Mile Range E-Cruiser

A 16-member team of Swiss university students—led by Dr. Josef Mayr, Marco Job and Dominic Schmid—may have designed the future of electric motorcycles, even if its project never gets off the ground. With a reported 250-mile range, we say Yes, please, to the Ethec.

The Current: E-Volkswagen Crushes Pikes Peak Record

French driver Romain Dumas obliterated the overall Pikes Peak International Hill Climb record on June 24th 2018, piloting his electric Volkswagen I.D. R Pikes Peak car to the finish line with a time of 7 minutes, 57.148 seconds, topping compatriot Sébastien Loeb’s all-time record from 2013 – by an outrageous margin of 16 seconds.

“I made no mistakes," Dumas said. "This race is so tough. I am so happy. We have worked six years for this race.”

“Since this week’s tests, we have known that it was possible to break the all-time record. For it to come off, everything had to come together perfectly – from the technology to the driver,” Dumas added. “And the weather had to play ball, too. That everything ran so smoothly is an incredible feeling, and the new record on Pikes Peak is the icing on the cake. I still cannot believe that Volkswagen and my name are behind this incredible time.”

Dumas was competing against conventional internally-combusted cars, one of them being motorcycle action hero Travis Pastrana, who won the Clubsport class in a 2016 Porsche Cayman GT4 in 10:33.9.

“Every employee involved in the Pikes Peak project has constantly had to push their boundaries and show extreme commitment and dedication,” Volkswagen’s Motorsports Director Sven Smeets said. “Without this, it would not have been possible to repeatedly overcome new challenges and come up with new solutions. It should actually be impossible to achieve all that and especially the all-time record in such a short time, but our team pulled it off thanks to their passion and commitment.

VW’s Pikes Peak car was announced on October 18, 2017 and Dumas crossed the finish line on June 24, 2018, just 250 days later. From prototype to fully-electric drive technology and battery management, Smeets and his team had its hands full in Wolfsburg, at the motorsport headquarters in Hannover, Germany. Most teams spend the month of June in Colorado Springs in intense preparation.

Jeremiah Johnson was the first electric motorcycle, at 40th place overall. He was racing on a 2018 University of Nottingham UoN-PP-02 bike, which took third place at the 2018 Isle of Man Zero TT with rider Daley Mathison two weeks prior.

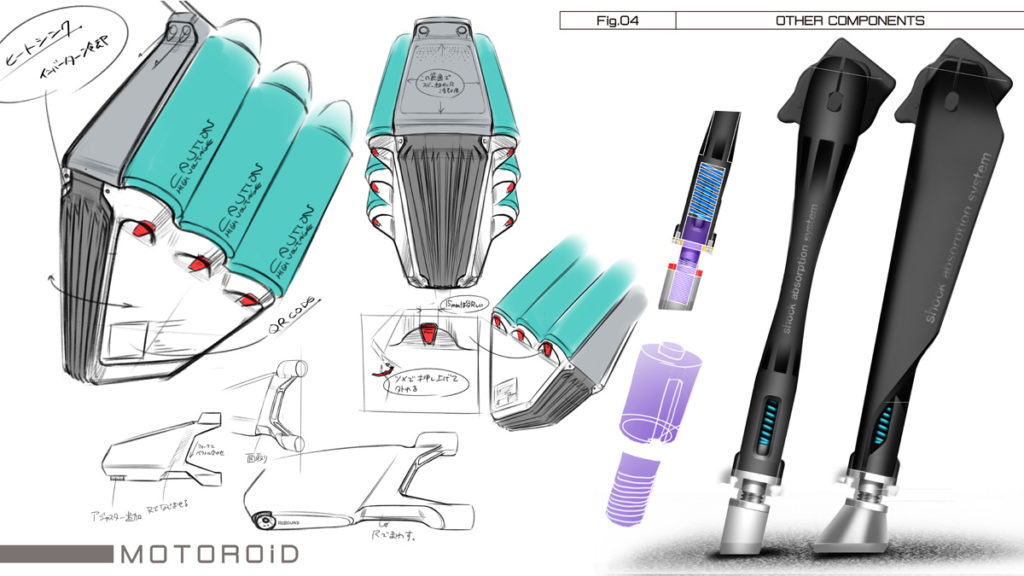

The Current: Experiencing Kando with Yamaha’s MOTOROiD

Torakusu Yamaha established his company as a piano and reed organ manufacturer in Hamamatsu, the Shizuoka prefecture of Japan, in 1887. Today, the company's logo is a trio of interlocking tuning forks. After World War II, company president Genichi Kawakami repurposed the remains of the company's war-time production machinery and the company's expertise in metallurgical technologies to manufacturing motorcycles [See our article: Japanese Motorcycling: the Early Days].

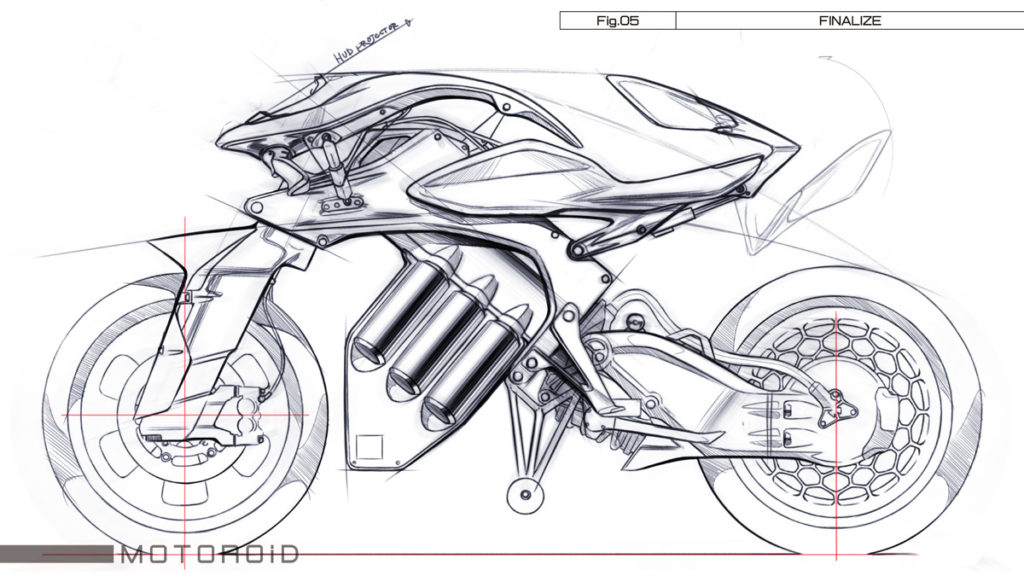

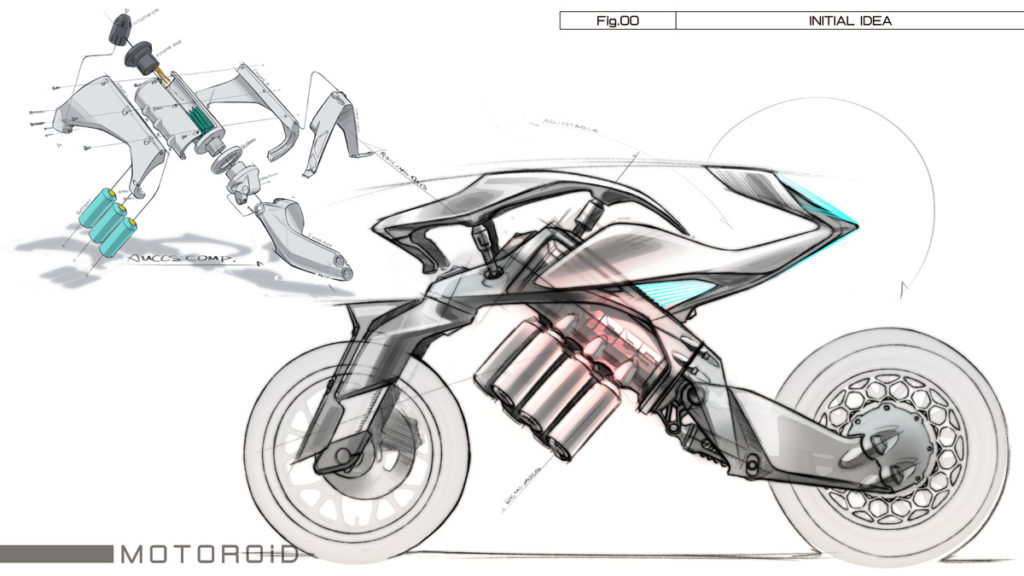

According to Yamaha, its aim was to “create a new-generation motorcycle in the unique style of Yamaha, so that when the rider settles into the racer-like riding position and grabs the handlebars, it provides a sporty and exciting riding experience regardless of the person’s individual skills or athleticism.” The world seems ready for this bike!

What lies beneath?

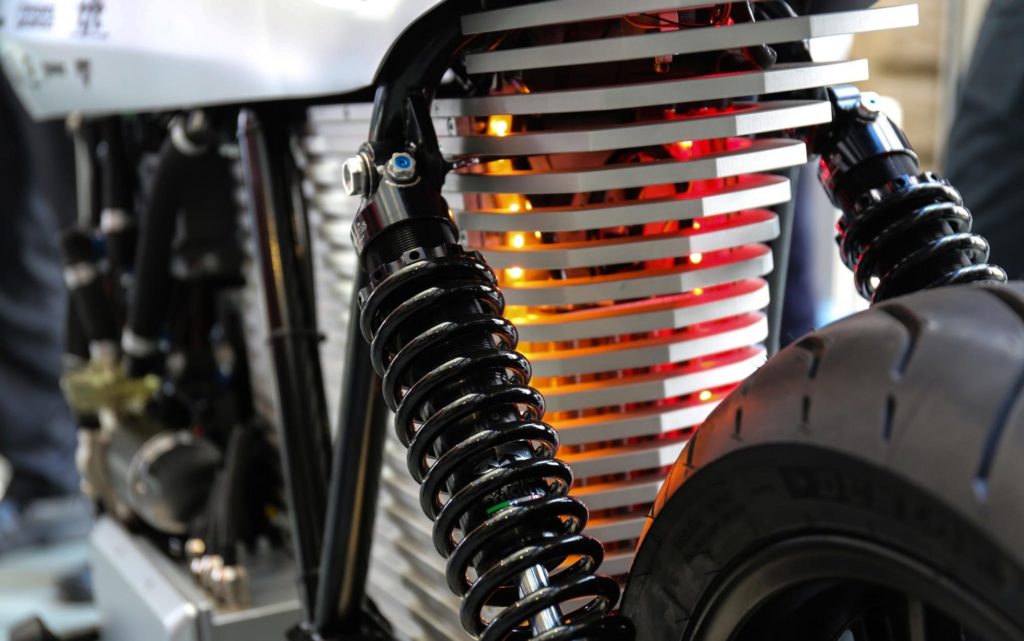

The 479-pound MOTOROiD is equipped with high-precision balance control via artificial intelligence and autonomous technology, and it can sense its own state and adjust its center of gravity accordingly to stand up off its kickstand and remain upright unassisted. It can also recognize its owner and move forward to meet him/her, as well as react based on its rider's actions thanks to its human-machine interface (HMI).

During rotation, the battery moves either right or left, acting as a counterweight that enables the machine to maintain balance and remain upright at a standstill. The inner frame unit area rotates around the AMCES axis via electronic control.

What does all this tech mean?

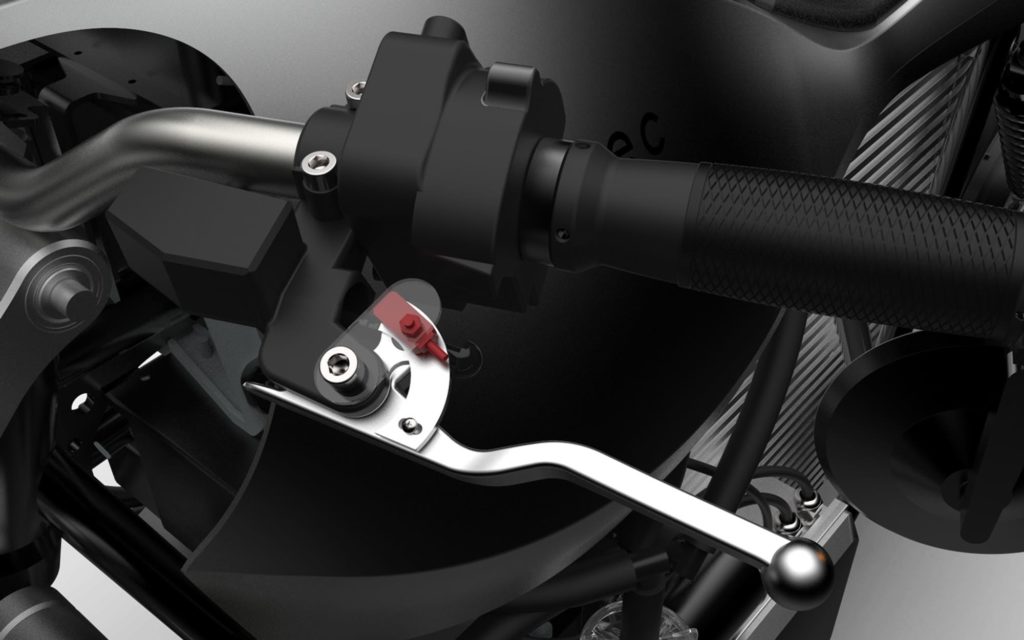

Control Unit: This integrates and controls all of MOTOROiD's functions and operations, from the image recognition artificial intelligence (AI) and inertial measurement unit (IMU) data to other various vehicle data. Thanks to high-speed processing, the unit can relay instructions to the entire machine for not only AMCES, but also the steer-by-wire system (electronic front-wheel steering inputs), kickstand, powertrain, HMI and more.

Main Actuator: The main actuator, which receives instructions from the control unit, rotates parts around the AMCES axis with high precision, thus controlling the machine's center of gravity. Besides the main actuator, MOTOROiD has several other large and small actuators.

Haptic HMI: MOTOROiD also features haptic (more commonly known as “force feedback”) devices. The haptic human-machine interface (HMI) works to provide a greater sense of unity between rider and machine as it contacts the rider's waist and chest area, as if the owner is being embraced by the vehicle. These contact points are aimed at a more intuitive form of feedback and interaction between the rider and machine.

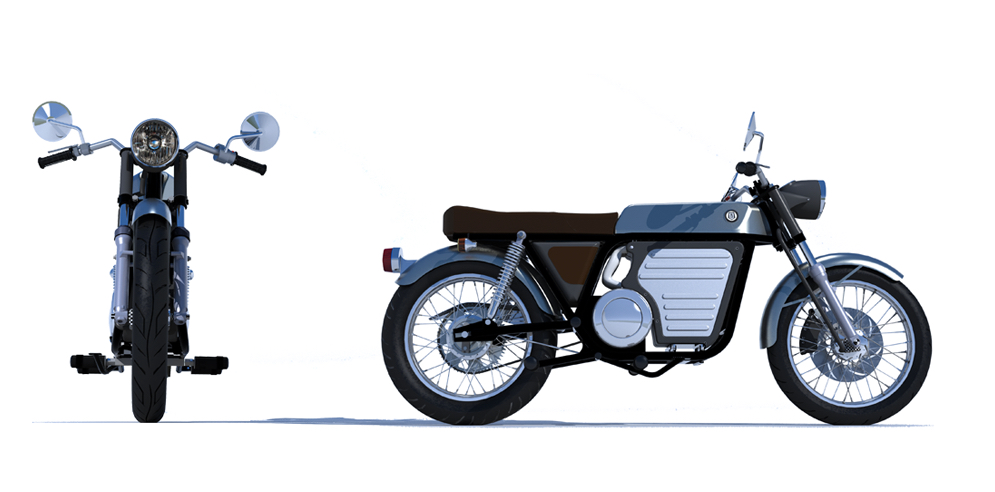

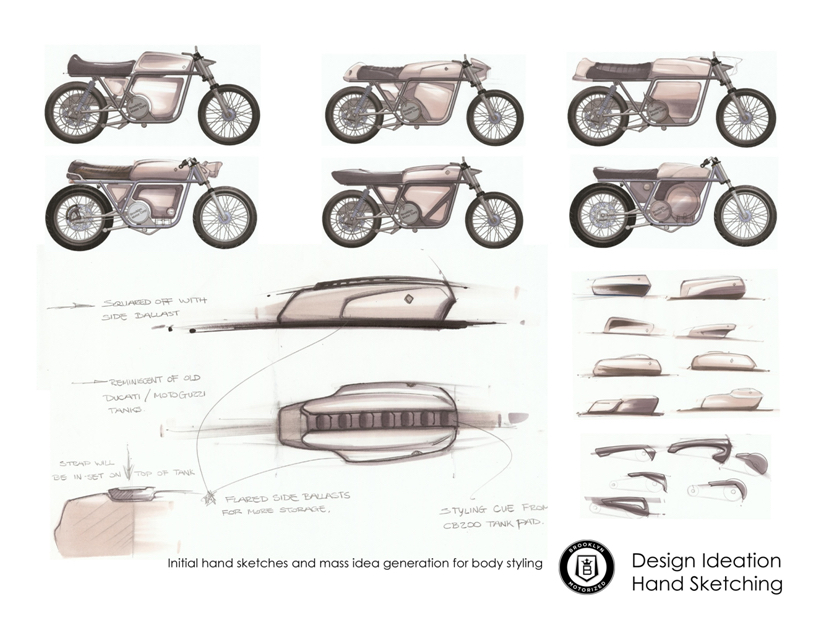

The Current: Exclusive! Gloria Factory of Paris

Recently, I reported on the French custom garage Jambon-Beurre Motorcycle, run by partners Benjamin Cochard and Antonin Guidicci. They were bitten by the e-Bike bug two years ago, and created a sublime one-off e-Tracker. As Cochard told me, they’ve been working on a proper production-friendly model, and here it is with a new name: Gloria. The team has expanded with industrial designer Vincent Graviére as a third partner, and the concept has evolved from the raw punch of the Jambon-Buerre into an appealing urban commuter, with the concept of being a fully customizable machine via an online visualizing system, with delivery to your door.

After a 10-minute run on our friend’s BMW electric scooter, we came back to the workshop with only one idea in mind: put this crazy technology into a cool body! We immediately fell in love with a magic mix of high power, high torque, constant push and silence. It makes you feel a new kind of freedom that a gas-powered bike cannot brings you. You feel like driving a Star Wars race ship in the city. It’s pure magic.

Problem is that electric high power technology and old school mechanicals are two different worlds! That is how we met the guys from Pymco, a French startup specializing in electric power management.

Together, we started to think about how could we mix ideas to put in the same bike, combining the savage spirit of `70s and `80s motorcycles, with the great modern electric power technology and the colorful street style inspired by the `90s kids that we love so much ?

So here is Gloria. Inspired by digitally native vertical brands, Gloria is the first fully customizable electric motorcycle.

Homologated like a 125cc motorcycle, you can drive it with a regular car license. But the acceleration is closer to a 300cc than a 125cc. With a 100 km range and 120 km/h max speed, Gloria is perfect for urban/suburban condition and riding it is as simple as riding a scooter.

No more dealership with 30 bikes aligned in the shop window, all the same, and a fat guy with a tie telling you to buy the one with the best margin.

Gloria is the first digital pure player of the motorcycle history. Go online, customize your dream motorcycle and we deliver it to your home. Wanna change the look of your bike? Just go back online anytime and make the modification on the app. It automatically plans an appointment with our services and we update it right to your tastes.

With Gloria, you don’t look for a perfect bike for you anymore; you just create the bike that fits you. And as the customization is done by the manufacturer itself, it’s fully legal on the road, which is very new in the custom motorcycle world.

We are still raising funds to finish the development and launch the production. First sales are planned for 2020.

The Current: Jambon-Beurre - Avec L'amour Des Français

Ah, the French*. Indelibly stained by fine wine, fresh baguettes in the morning, the faire la bise (the double kiss on both cheeks), and a genetic grasp of joie de vivre. While their 24 Hours of LeMans is one leg of the Triple Crown of Motorsport (with the Indy 500 and Monaco Grand Prix), their contemporary competitive motorcycle output is minimal today, a situation that rankles many natives. After all, the French invented the automobile (1770), were first to patent the motorcycle (1870), built the first motorcycle industry, and pioneered every engine configuration used on motorcycles today - check out the 1914 Peugeot racer with four-valve heads and double overhead camshafts!

[*with Boulanger as author, and d'Orléans as editor, there is obviously no DNA conflict of interest in this article]

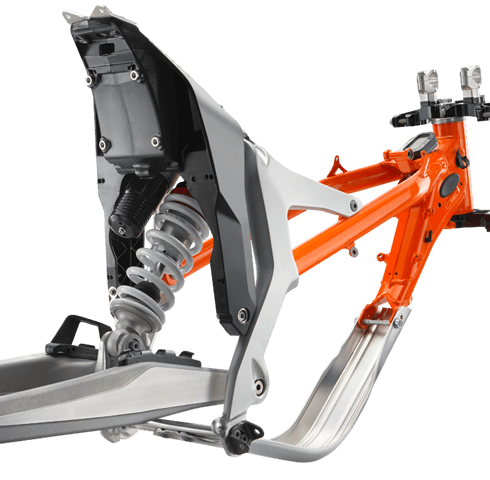

The Current: KTM Goes Silent With Freeride E-XC

Austria’s motorcycle juggernaut KTM saw the e-train a-comin’ 10 years ago, when its Mattighofen R&D unit began developing electric models. Last autumn KTM introduced its second-generation Freeride E-XC, which recently arrived at select US dealers, boasting 18 kW (24.5 hp) of peak power with 42 Nm (almost 31 pound-feet) of torque for 90 minutes of silent dirt-pounding.

In addition to the 245-pound Freeride E-XC, Pierer plans an e-mini and an e-scooter, with an emphasis on machines from 250 watts to 11kWh as technology evolves and consumer demand increases.

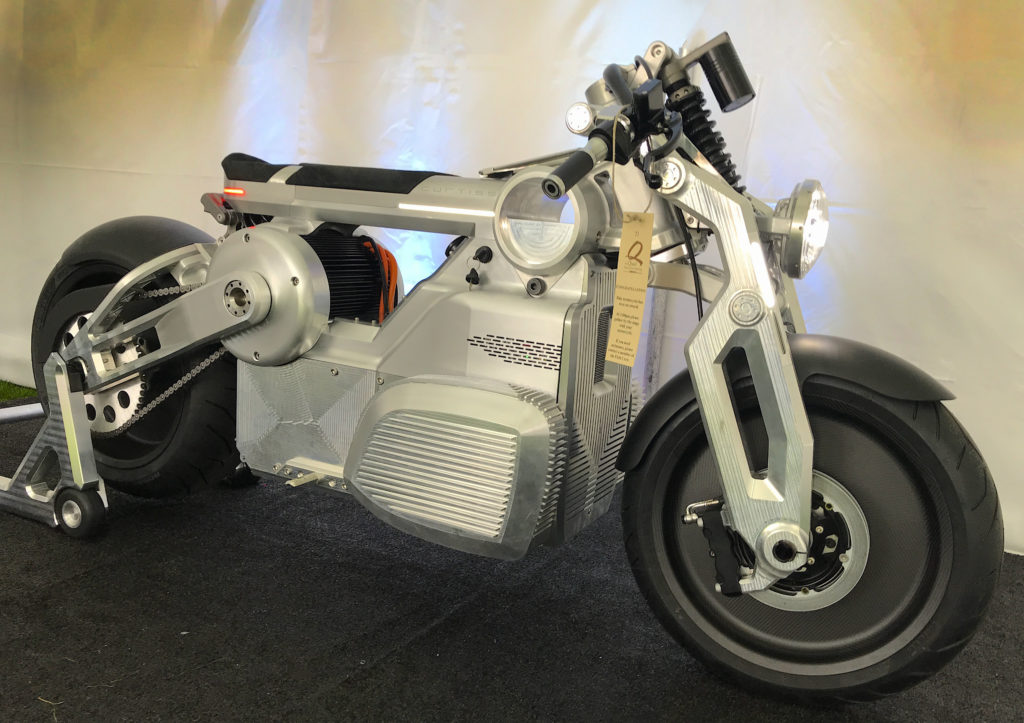

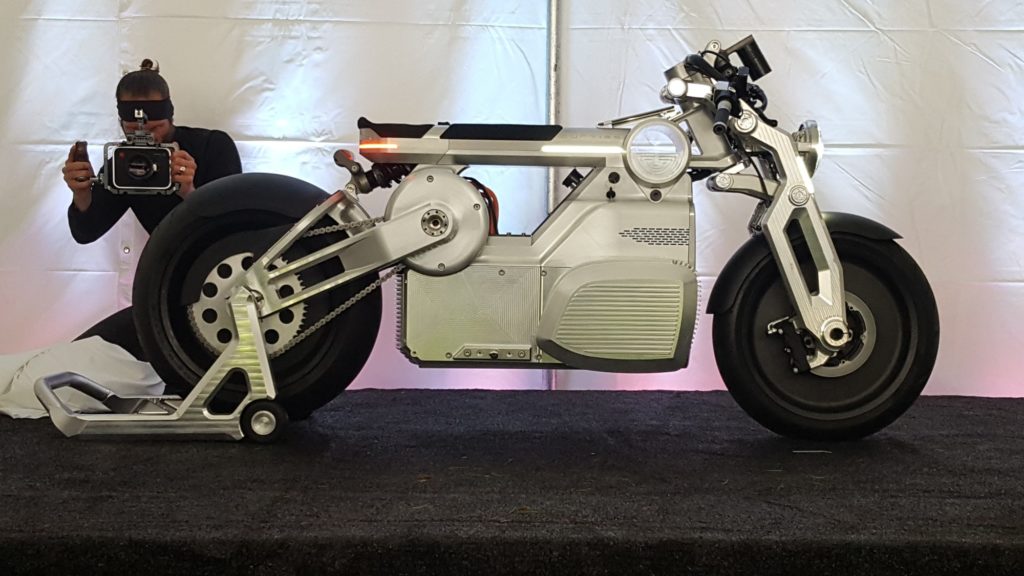

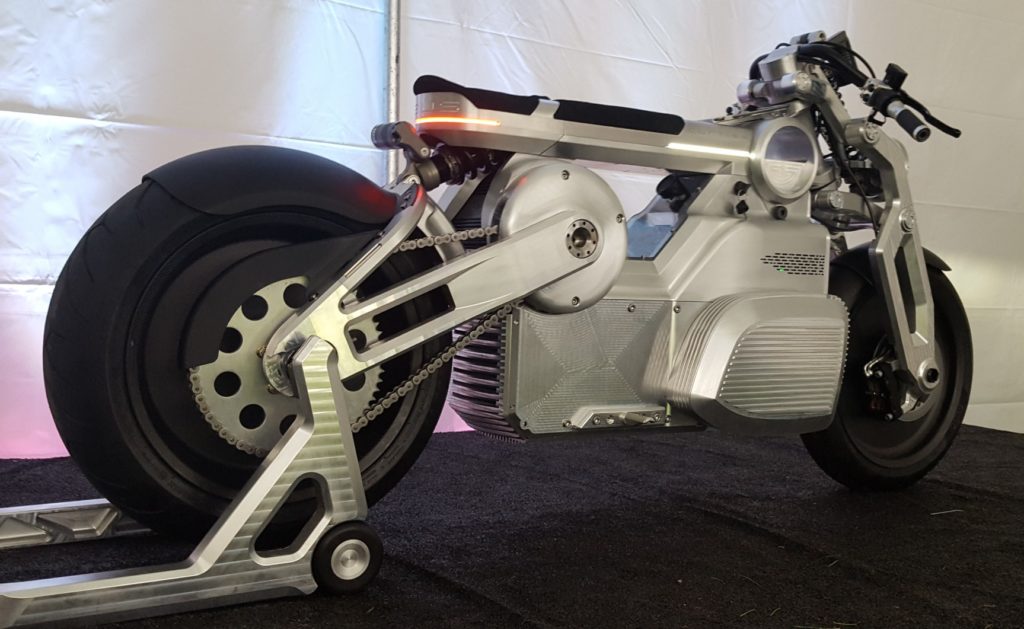

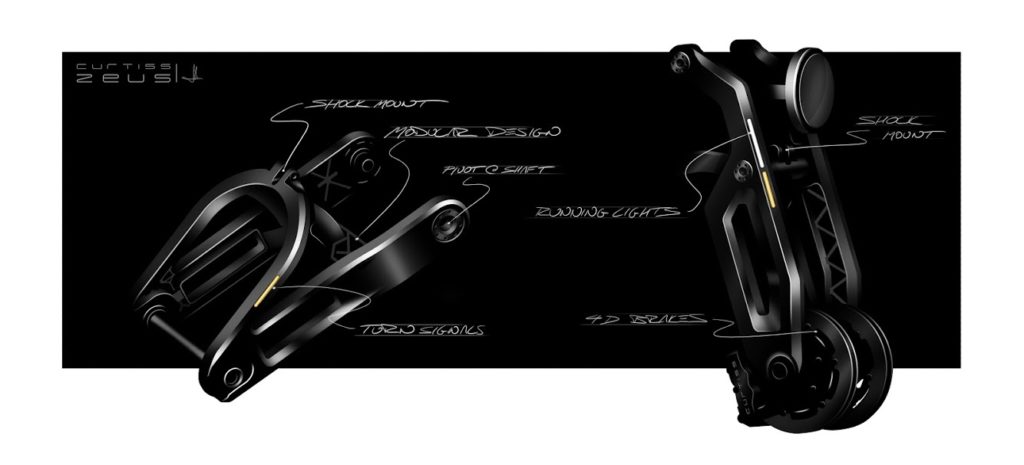

The Current: Curtiss Unveils The Mighty Zeus

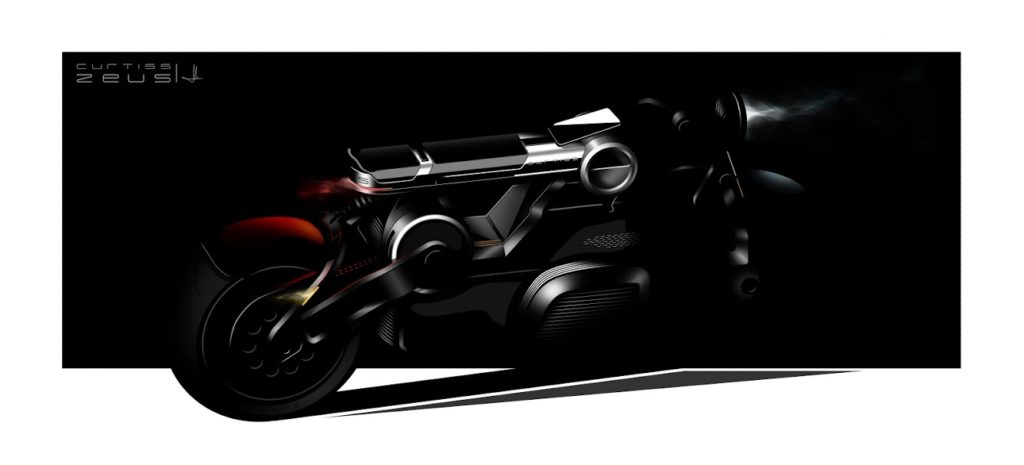

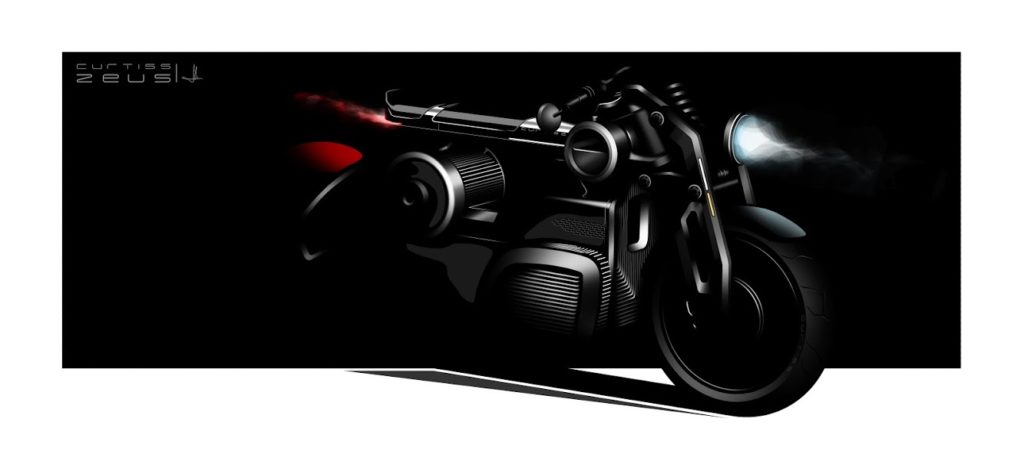

In one of the most eagerly-anticipated e-Bike launches, Curtiss Motorcycles lifted the wraps off its Zeus e-Bike at The Quail Motorcycle Gathering in Carmel, California, on May 5th. Company founder Matt Chambers had claimed, “We’re going to create a new environment for the second and third year onwards—going forward based upon what our projections are, and I think we’ll have a pretty good idea from when we strike the match on May 5.” True to that promise, the Zeus is slated to commence production in 2020, after further development, and taking the temperature of their customers' reactions to the radical new machine unveiled at the Quail.

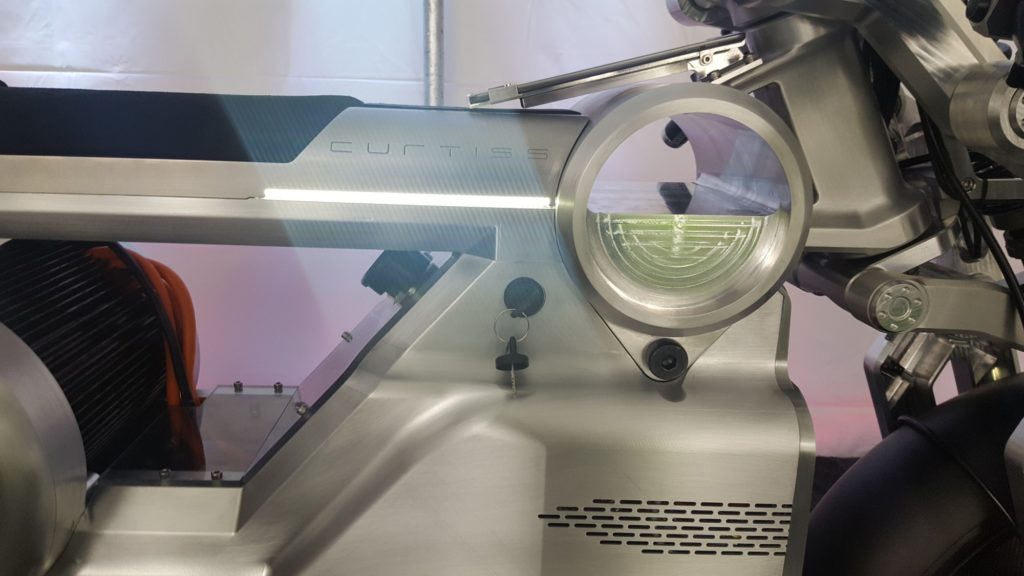

'T' shaped battery compartments [Paul d'Orléans]

Jordan, walk me through the design process timeline from last August when Matt Chambers announced that his company was going to change its name and design focus.

"By the time the announcement was made last year by Matt, this project was already deep into development. Curtiss as a brand has been in development for almost eight years now, and Zeus specifically started on the drawing board about two years ago.

For the last three years, I’ve been carefully developing a new design DNA for the brand, and Zeus is the first product from us to showcase that DNA publicly. Many other products have been in development alongside Zeus, so those products will be making their debuts soon."

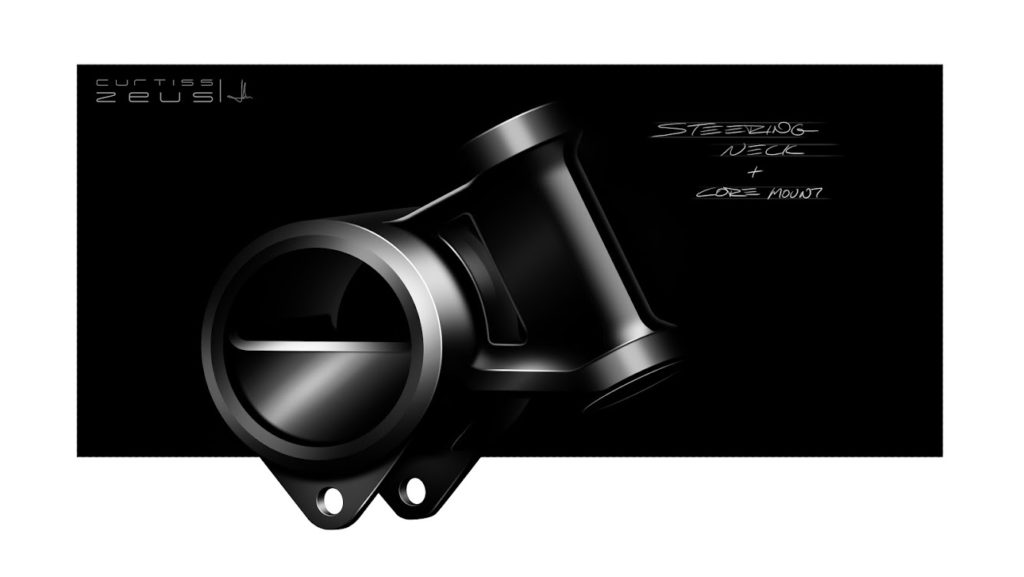

"Zeus specifically came onto the drawing board approximately two years ago. Before that, the discussion had existed for several years. Internally, Curtiss knew that it was time to create an honest electric motorcycle, so the company spent years exploring what that meant. Zeus showcases Curtiss's first battery configuration, internally labeled ‘T-Block’.

Alongside Zeus, several other "Block" battery configurations came to exist. Curtiss design DNA is organic, pure, and simple minimalism. In order to be sure that Curtiss products maintain that DNA is critical, so the process takes time; sometimes, it’s necessary to even get out of the way and allow the products themselves to organically become what they want. It’s a process that cannot be rushed."

"I agree 100 percent! The number one driving factor behind the design/style of a motorcycle is its package. ICE motorcycles all have, more or less, the same components, so they have all grown to accommodate similar looks and proportions. Electric motorcycles have completely different components, so there’s no need for them to look, or be packaged like, traditional ICE motorcycles. This is where we believe our industry is missing the mark.

Today’s electric motorcycles appear to have been designed around traditional ICE motorcycle packages, proportions, and styles. This has led nearly all of them to have faux gas tanks and other aesthetics that we believe to be dishonest to the technology that they carry. With Zeus, and its siblings to follow, Curtiss has redefined the package and layout of the motorcycle. We have arranged the new electric components in ways that we believe are advantageous over ICE components in terms of weight distribution and rider ergonomics."

"From the moment I was hired on at Curtiss, Matt has given me zero limitations. He’s created a culture within our brand that allows my creative department the freedom it needs to generate new, exciting ideas and execute on them. Although I have the capability to design and think so freely, that does not mean that I don't tap Matt's extraordinary wealth of knowledge in motorcycle design, specifically proportion.

With nearly 30 years of executive experience in our industry (more than most), Matt has a near infinite understanding of motorcycle design, which has been an invaluable asset in creating this new brand family."

"The Zeus concept prototype that we showed at The Quail this year is slated for a 2020 model year production release, with production likely beginning in early Fall 2019. Our long-term product strategy includes having models positioned at a variety of price points, meaning there will be something available for nearly every pocketbook. These models will include a great selection of genres, forms, power, and range that will satisfy the needs of every rider out there. Every single one of these models are already in design and development."

The Current: Silicon Valley On An Energica Esse Esse 9

The peninsula south of San Francisco has legendary motorcycle roads in the hills above 'Silicon Valley', which is ground zero for global technology, and the home base to Energica's US operations. Energica distributor Stefano Bennati is a former Maserati employee who, like the electric sportbikes he promotes and distributes from Redwood City, comes from Modena, Italy. That small commune in northern Italy is a hub for fast, exotic fun, were machines from Energica, Ferrari, Pagani, De Tomaso, and Maserati are made, making it one of the most famous places in the world for motorsports fans.

This an Italian product, so it must look good! A steel trellis frame, aluminum swingarm and hand-machined components, more metal than plastic parts, and solid contemporary design add up to a beautiful bike. Spokes instead of mags with a front gold rim, and rear gold hub are just part of the subtlety. Brand-name parts from Brembo, Marzocchi and Pirelli legitimize the chassis components. Onlookers are hard-pressed to believe it’s electric - until you turn the key and twist the throttle.

The 31-inch high seat is narrow and long enough for comfort, and someone certainly spent time choosing handlebar rise and width. The Esse Esse 9 feels like a proper street fighter before takeoff. The machined pegs are right where they need to be, even for a 6-foot-1 rider like me.

On take-off, the synchronous oil-cooled motor hums to life in a faint shrill, gaining decibels as the chain drives the 17-inch rear wheel into motion. On our ‘spirited’ ride into the quaint Northern California village of Woodside, the Esse Esse 9 was roaring like a banshee before I spotted a motorcycle cop pulling over a motorist.

How does it ride?

All proper streetfighters need to be versatile, providing performance while staying comfortable. The Esse Esse 9’s throttle control is designed with a rotary potentiometer and a safety microswitch, detects the rotation of the throttle and is activated every time the accelerator is engaged or released.

The VCU manages both the potentiometer and the switch signal to fine-tune the torque demand to the engine based on the mapping selected, while the microswitch is used as a safety feature in case of malfunction of the throttle control. Our ride was almost too smooth, forcing me to throttle lighter than normal. And at 34.5 inches wide it’s primed for California lane splitting.

How fast can it go?

Energica claims 133 ft lb of torque and 109 hp, so getting the bike up to 125 mph in Sport mode tout de suite is no problem, but that's where the top speed limit is programmed. And of course, the higher the speed the quicker the battery charge drops, so speed demons better know where their next charge station can be found on longer rides. Several smartphone apps exist to lessen the worry.

Compared to the 463-pound Ducati SuperSport S or the 443-pound Yamaha YZF-R1M performance-wise, the Esse Esse 9 weighs 570 pounds. The extra 100 or so pounds comes from the patented Energica lithium polymer battery, capable of 11.7kWh. Thankfully the bike has a reverse mode to assist if you get into a parking pickle.

Energica claims 125 miles in Eco mode, or 93 miles including highway and street use. But the Esse Esse 9 offers four riding modes to use only the energy necessary under certain circumstances: Urban, Eco, Rain, and Sport, with four regenerative maps (Low, Medium, High, Off) to make wise use of the speed you’re scrubbing. The Long Period Rest function allows the maintenance and automatic balancing of the batteries during a long period of non-use.

How much?

Compared to its high-performance cousins the Ducati SuperSport S ($14,995) and Yamaha YZF-R1M ($22,999) the Energica Esse Esse 9 is $24,940.Warranty is three years on the bike and 31,000 miles on the battery.

The future of racing is electric

For 2019, the governing body of international motorcycle racing has partnered with Dorna and Italian power company Enel to develop the FIM Enel MotoE World Cup. Energica was chosen to provide the spec bike for the 18 riders scheduled to compete in five European races, quite a coup for the company, which has competition from e-Bike manufacturers around the world...but none from Modena!

The Current: Talking Conversion With Night Shift’s Matt Candler

Would you immediately dismiss someone with ideas about re-imagining motorcycles, if they were an educator with no formal motorcycle design or engineering credentials, and if they started riffing on ideas including golf cart parts and Nissan Leaf batteries? I think most of us would be suspicious, but then again, sometimes it takes an outsider to re-imagine an industry. And maybe the motorcycle industry could learn something from a New Orleans grease monkey named Matt Candler.

Matt, why and when did you start tinkering with motorcycles and batteries?

I moved to New Orleans in 2006 after a few years of garage-less living in big cities. Our new place had a too-small-for-working-on-cars garage, and as soon as I cleared it out, I started looking for projects that would help me justify buying new tools to my wife. I'd been commuting on two wheels for a while—a heavily modified 4-stroke scooter in San Francisco and an electric GoPed in New York City—so it wasn’t long until I dropped $40 on a copy of John Bidwell's guide to converting a Honda Rebel to electric, called 'El Chopper ET.'

For someone who's not an engineer you've certainly garnered a lot of press. What is your day job, and how do you approach a build?

I finished college with math and Spanish language majors, but I spent more time in the darkroom trying to become a photographer and in the metal studio dreaming of being a sculptor. I think that’s one reason I’ve found this whole process about way more than horsepower and specs. It’s really about learning for me, despite not having a credential or formal training. How can I figure something out without a degree? Where are the informal networks that can replace the formal classroom stuff I missed out on?

I build with two things in mind:

- Looking for new lines: What frame could be really interesting without they constraints of an ICE drivetrain? What’s something we haven’t thought of?

- Learning from other people: What do I suck at that might get better if I try X, and who can I find who knows how to do it better than me? Where can I go to explore what learning for learning’s sake really looks like?

Looking for new lines

My first build took more than a year, and I wanted to see results faster, so my second build was much simpler, a mod more than a ground-up build. The factory Zero I bought kept begging for some mods, so I put a café spin on it. I thought that Zero looked much better when I tore all the plastic off.

Stripping off the bodywork and looking for new design lines is really interesting to me. And it is what I obsessed about in my last build, based on a Suzuki Savage 650 frame and 14 battery modules from a Nissan Leaf car.

Learning from other people

One of the reasons I’m so interested in people like John sharing what they’ve learned is because I work in education during the day. I work at an organization called 4.0, where we help people run small experiments that might make learning more effective, engaging and fun, especially for kids who don’t have great school options today.

That’s why I get so fired up when I find a community that’s together solely for the love of creating and sharing and learning. From elmoto.net, an online community of electric builders, to Makers of NO and the New Orleans Mini Maker Fair, I’ve found places I can go when I’m clueless or when I’ve figured something out that I want to share.

You're talking my language with a 1973 BMW R75/5 build. How's that coming along, and what are your plans?

Thanks. The airheads are gorgeous bikes. When I took the Leafy Savage to the Handbuilt Show two years ago, I got to spend time with some builders I really respect, including Bryan Heidt, who builds bikes at Fuller Moto in my hometown of Atlanta, GA. He pushed me on my build, and dared me to try and make an electric on a really classic frame. I took him up on it and got a prototype built last winter with the help of two amazing interns who were as curious as I was about learning new stuff, Liam Grace Flood and Nadav Hendel. We documented that journey here.

I’d love to get feedback on where to take this!

Any plans to partner with an OEM to develop a production-friendly model?

Nope. I’m lucky to have a day job I love. I love seeing OEMs experiment with custom builders, and I’d be thrilled to riff with anyone thinking about electric bike design, but I’m happy as a dude in a garage right now. I care more about encouraging people to get off their couch and try something new than getting lots of bikes to market. I respect the people who take on that challenge, but that’s not my goal right now.

The Current: Wannabe AlSi9Mg E-Chopper

Enrico “Ricky” de Haas doesn’t subscribe to the notion that future-forward electric motorcycles need to resemble futuristic science experiments. In fact, his Wannabe-Choppers AlSi9Mg—handbuilt in his Hüttenberg, Germany shop—is more a throwback than advancement in aesthetics, but that’s what he likes about it. His attitude reflects the laid-back nature of his community in the Taunus foothills.

What's the inspiration behind building an electric chopper that looks so 'old school'?

The idea to build a 'hidden' electric chopper came about 12 years ago. Back then the idea was not to build it in an old-school way. Battery technology was way more expensive than today, so after failing to find a customer or sponsor for two years we shelved it and I started working on my first Harley project. Then I started casting.

How long have you been casting your own bike parts? The e-chopper looks like a master class in metal casting!

I’ve been obsessed with building a complete motorcycle from scratch since I was 15. This includes everything: frame, motor, transmission with all their internals (even the valve springs) to the tires. This meant I had not just to learn everything about motorcycles, but also everything about the production techniques, as I wanted to make everything with my own hands.

I understand you're planning another e-chopper that's more refined and faster?

We started planning the next two bikes on the day the AlSi9Mg was finished. Both will go in the same style direction: one will hopefully be powered with our own ICE and the other will have two very powerful electric hub motors, each several hundred Nm. One in the rear wheel and one in the front. But it’s very tough to find the time and the money to make this happen. A few days ago we ordered a new frame jig to start with the electric bike! Hopefully the next months will be productive.

You recently toured the American custom bike shows; did you get any orders? If so, what would a hard-working woman or man pay for their own Wannabe e-chopper?

The trip to the US did bring us a lot of orders for production and one of parts, but as of today no customer for a bike. But you never know. A bike probably would start at roughly 80,000 euro and will go easily up to 250,000 euro, especially if we build a one-off motor in house.

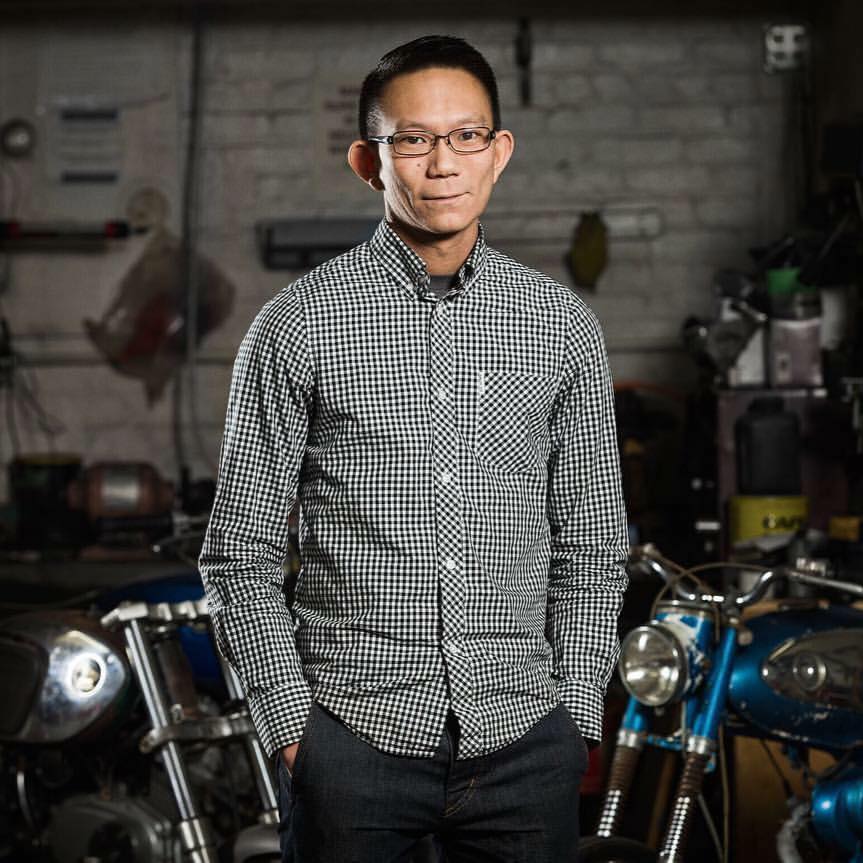

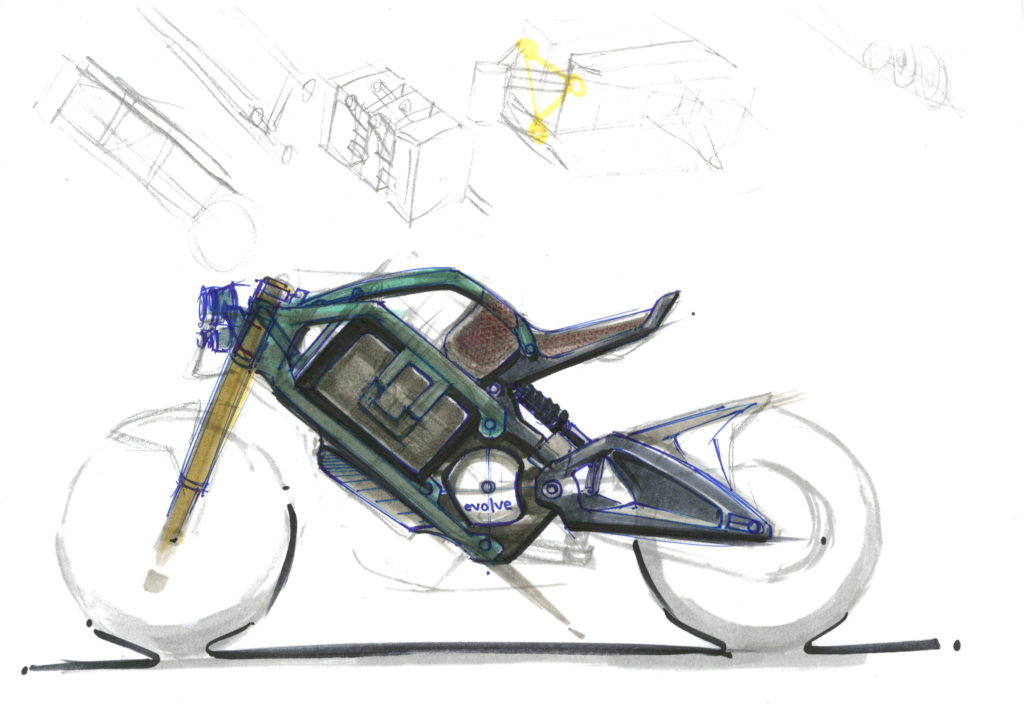

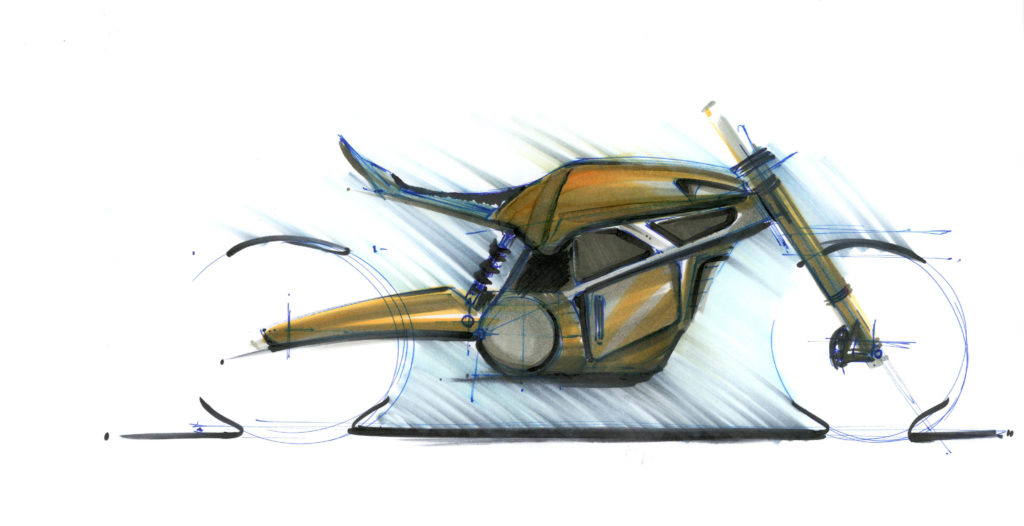

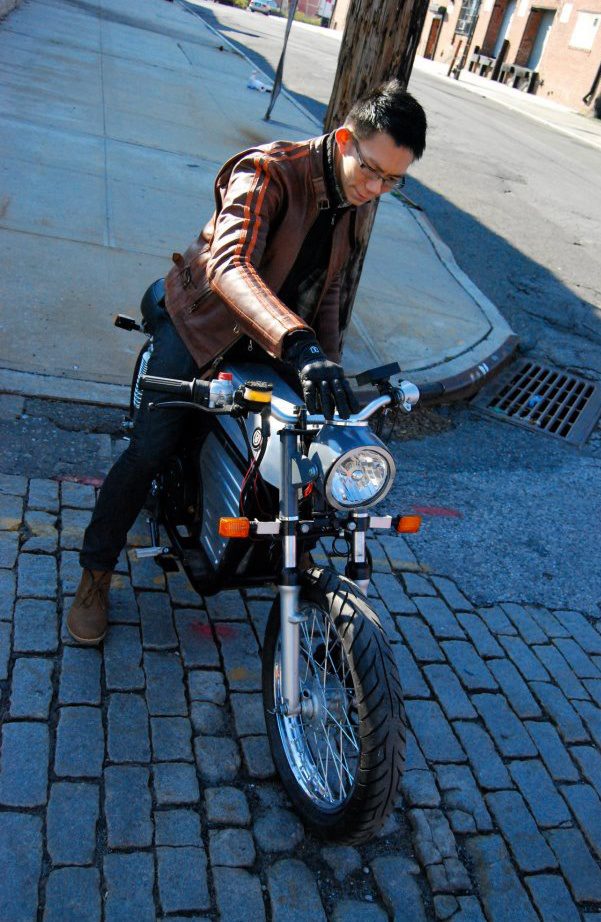

The Current: Hard Wired With Lawrence Au

Lawrence Au was born in New York City in March 1986. Unless you're in the NYC vintage bike scene, a Pratt Institute Student, or a connoisseur of electric motorcycle companies, you've probably never heard of Larry. He's been deeply involved in 3 electric motorcycle startups, and now teaches in the Industrial Design department at Pratt, while consulting with companies on motorcycle and product design, with manufacturing and production his specialty. He also runs a co-operative motorcycle parking garage and shop space in Brooklyn.

Larry, how and when did you take an interest in motorcycles, and when did electric take over your brain?

I've always had an interest in anything and everything mechanical even as a child. I wasn't exposed much to motorcycles, but probably around the age of 9, the transportation bug started with automobiles. Both my uncles were into automobiles, one was a BMW guy the other was a Mercedes guy. At that time, they were both looking for new vehicles and I remember grabbing every issue of Auto Trader at the supermarkets when I would go with my mother. Constantly flipping through each page in search for the golden treasure to show my uncles that weekend. After that, the bug of grabbing motorcycle magazines and flipping through them to study every aspect took place.

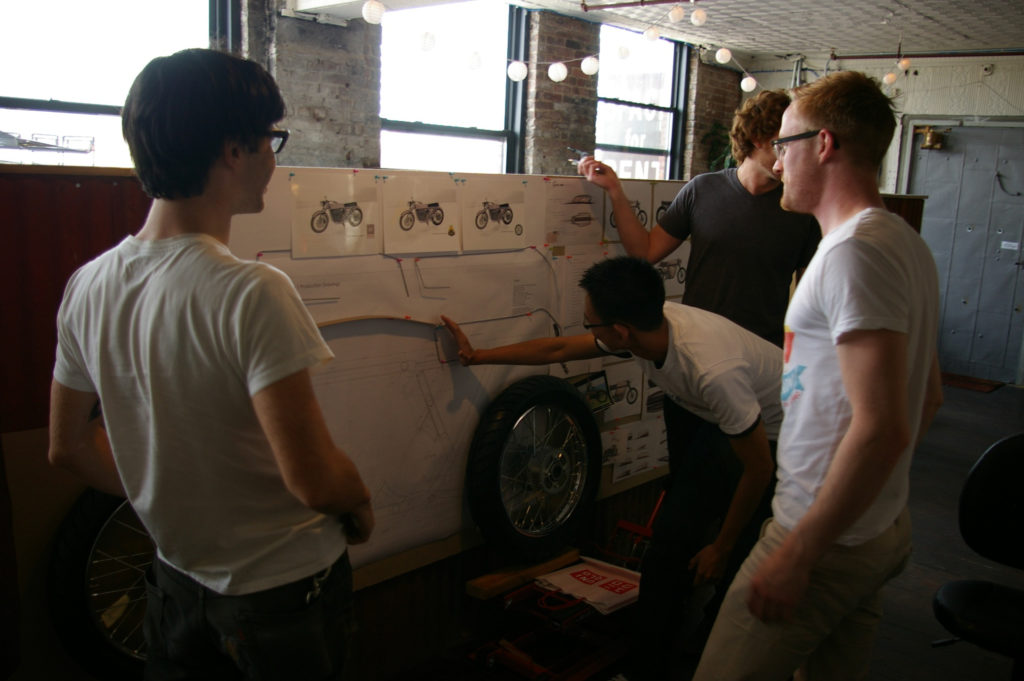

Tell me as much as you can about the three electric motorcycle companies you were involved with, and what you learned from each experience.

Brooklyn Motorized was the first, and most of it is explained in the previous question. But that company really was the most amazing team of people who were all genuinely enthused to be there. We got up every day to work 12-14 hour days, hit the bar a little bit after and went home to do it all over again the next day. There was not a single day that it felt like we were at work. If anything, I should have been slightly more selective about interns at the time. There was one summer that we regard fondly as the summer of "Intern Army". We had at that point maybe somewhere in the area of 30 interns, that we had to rent a separate space next to our offices in that building just to house everybody.

Currently, I am helping out another New York-based electric motorcycle company which shows promise. Not everything is finalized yet so I will not mention them.

But in the 10 years of working as a motorcycle designer, I have also worked manufacturing and production of large scale and volume industrial products, web dev app mobile technology, and general product design. I believe every different job I took made me a better designer, because I did not fall into the usual ‘industrial designer’ aspect of doing transportation design. I was for a long time the mechanic at the receiving end of these products, I was the racer/tuner, I was the guy designing and checking the frame jigs and injection molds, so I'm going to have a very different view on them as we go through the development process.

Do you think all three were ahead of their time, and maybe consumers weren't quite ready for e-bikes?

They weren't necessarily too early in certain aspects, but yes; as a majority we still aren't there yet all the way for EV. Look at Brammo and their 10 years of development with the Enertia platform that lead to what is Victory's e-bike. I haven't had the chance to ride one yet, but that six-speed transmission is something I'm not 100 percent certain yet is fully worked out. I tried doing it; damn it’s hard to resolve! As a general whole, the battery technology from 10 years ago hasn't changed all too much as far as the cell formulas or chemistry, the prices have just dropped. But with Brammo and Zero being in the market eye for a while and companies such as Energica that have been pushing towards racing, I think the general public have started taking e-bikes more seriously. I just truly believe that electric motorcycle companies need to position and prove themselves to be first and foremost bike people. That it is all driven by our passion and love for motorcycles and our community. Bikes are great, but our friends in the industry and community make it better.

Which motorcycle/moped/scooter companies do you follow and why?

I follow Indian and Harley-Davidson, of course. I was born and raised in the US, so I would love to see them make a strong comeback to try and match the numbers of the European and Japanese companies. I'm a bit of a secret American redneck at heart even though I live in NYC. Last year, Keino and I took a road trip to Milwaukee since he was showing one of his bikes at the Mama Tried Moto Show and we went through the Harley Museum. That was really eye-opening for me since I've never been that large of a Harley person since the only experiences I've had previously with them were working on the factory XRTT and KRTT race bikes at Team Obsolete. But walking through the museum really made parallels with my early experiences and grassroots bootstrap scenarios I've experienced and keep experiencing to this day.

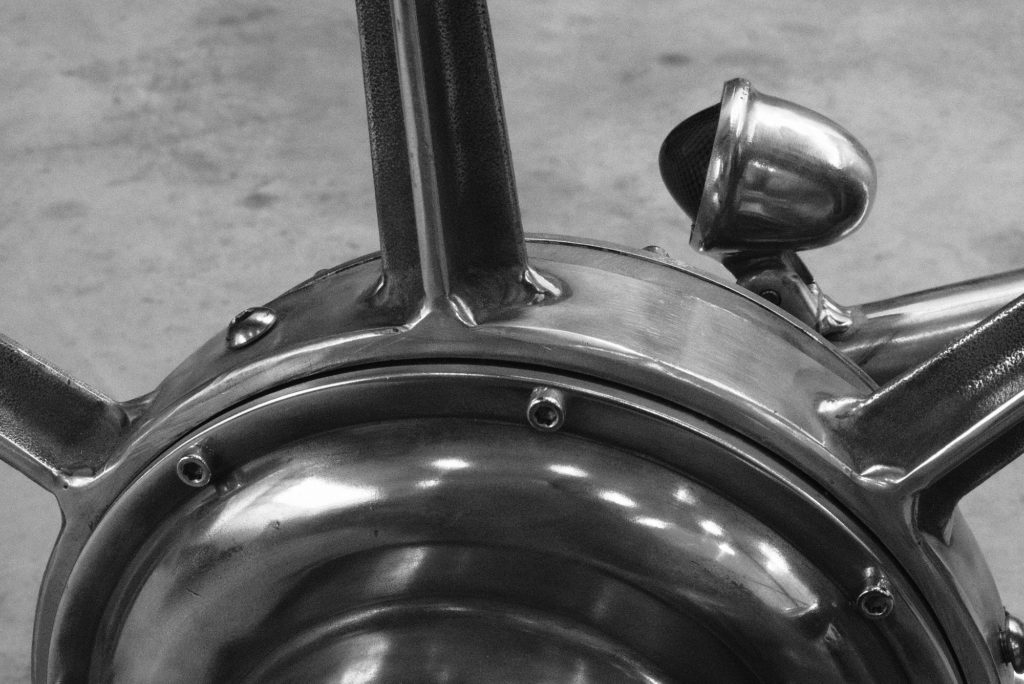

Do you have more modern e-bike designs and concepts bouncing around in your head?

Hell yes! I've been trying to scrape up some extra cash to make a new design (frame, motor assembly, battery enclosures, etc.) I've been working on for an e-bike concept. There's also been a interesting modern girder type fork I've been toying around with that I would like to CNC and play around with the geometry.

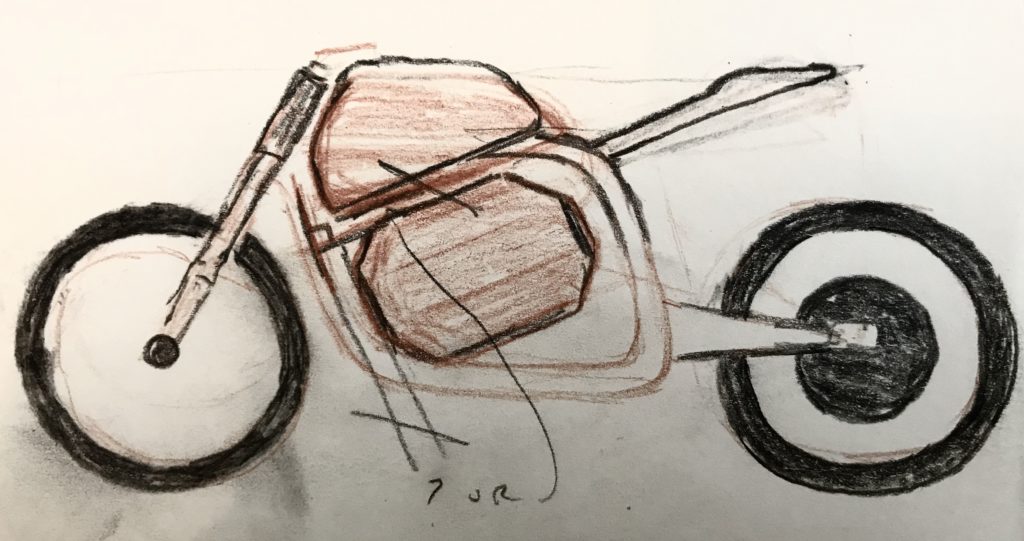

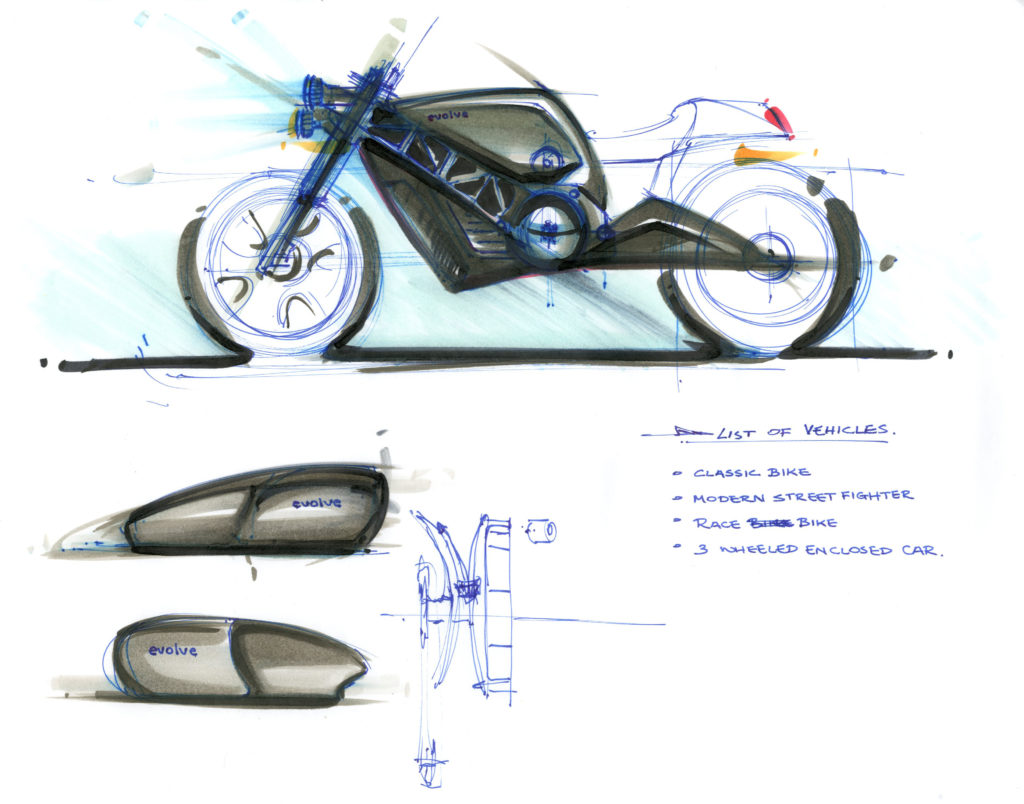

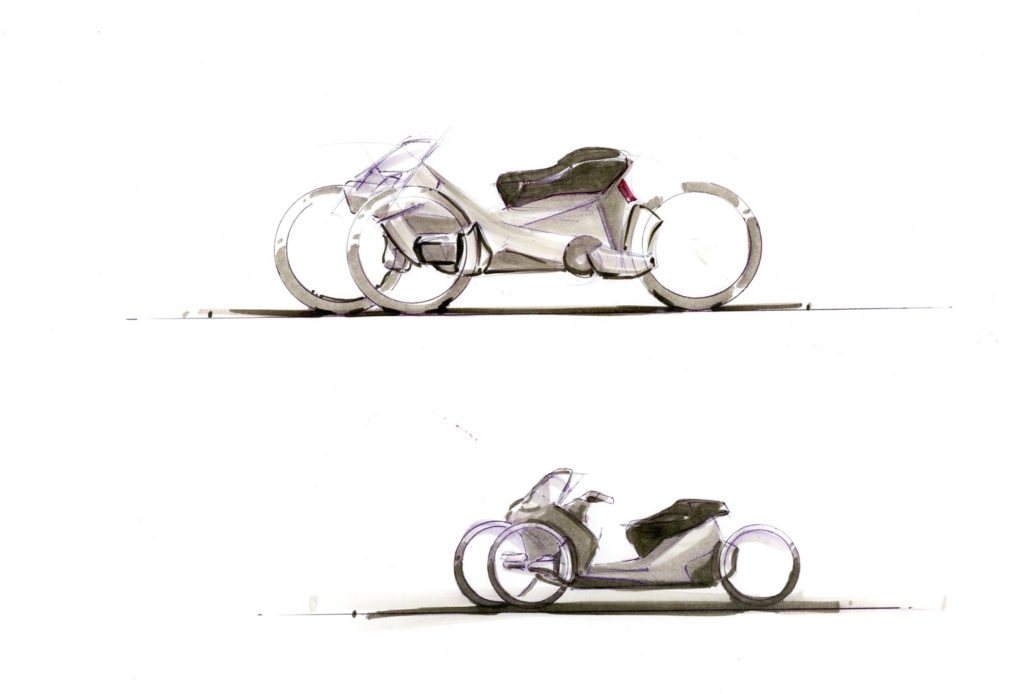

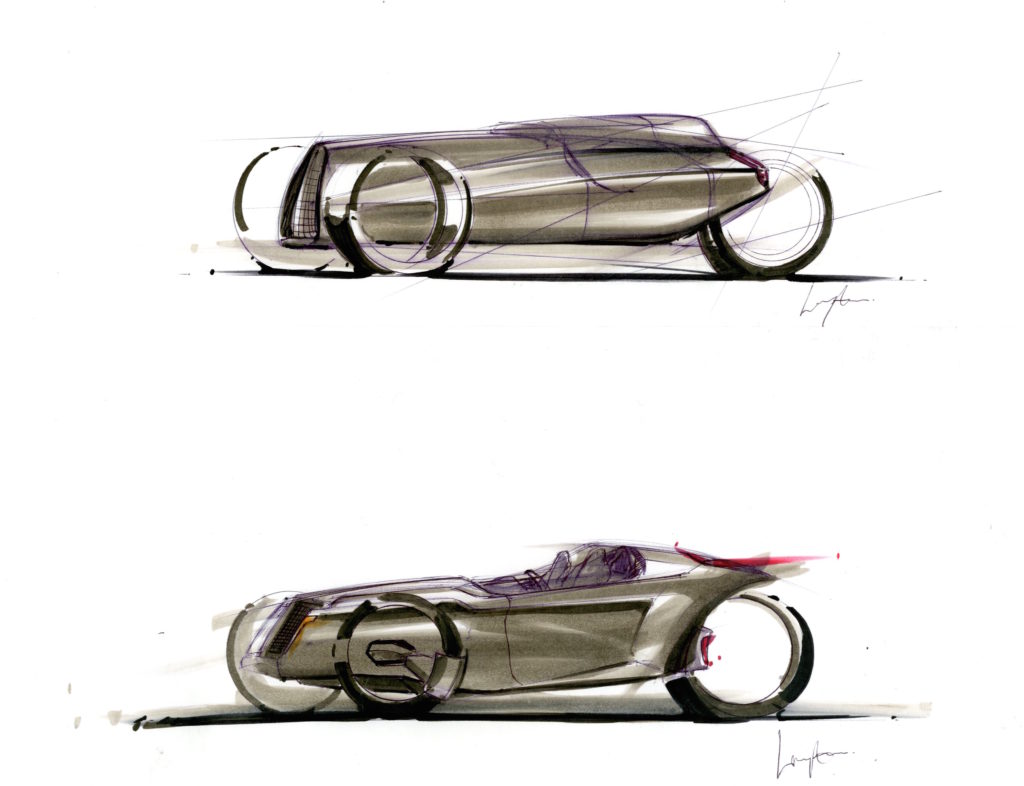

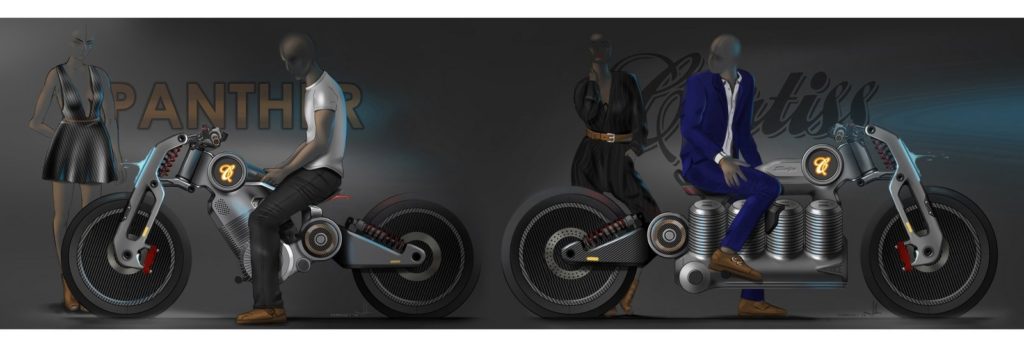

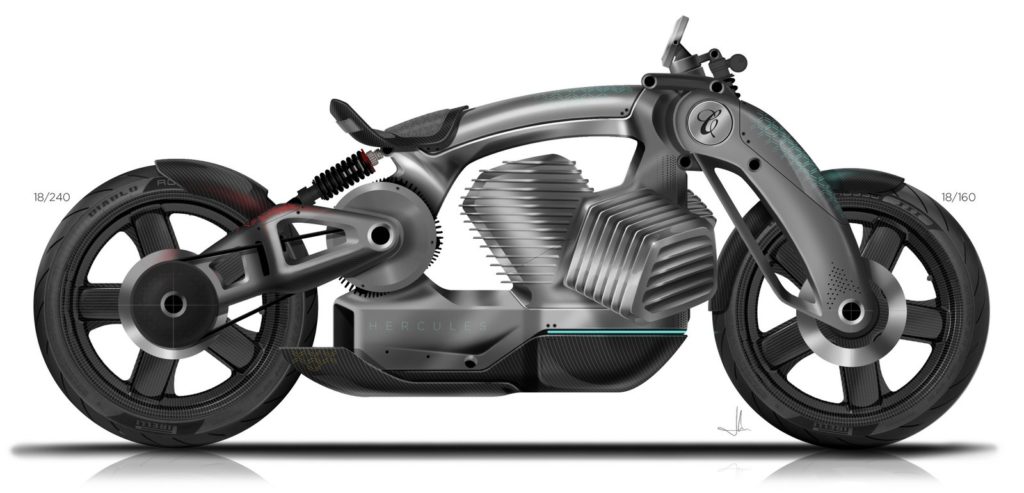

The Current: Curtiss E-Bike Concepts

According to Confederate-now-Curtiss Motorcycle founder Matt Chambers, if Glenn Curtiss were to launch a motorcycle company in 2018, he would use electric power, just like he pioneered the American V-twin back in 1903. Chambers will reveal to the world his Curtiss Hercules e-bike at The Quail Motorcycle Gathering in Carmel Valley, California on May 5. Curtiss has partnered with Zero Motorcycles for their drivetrain, and the target retail price of the Hercules is $30,000, a far cry from the $100,000-plus the retail price of Confederate motorcycles over the past 25 years.

According to Chambers, the first 300 bikes will be built at his facility in Birmingham.

“But we’re going to create a new environment for the second and third year onwards—going forward based upon what our projections are, and I think we’ll have a pretty good idea from when we strike the match on May 5. Probably by the end of May we’ll have a good sense of what the interest in this program is going to be, and whether or not there really are people out there in their thousands who want to purchase a Curtiss E-cruiser—is it thousands, or is it hundreds, or is it tens of thousands?”

The Current: Meijs M-M-Motorman E-Moped!

“Simplicity is not the absence of clutter, that's a consequence of simplicity. Simplicity is somehow essentially describing the purpose and place of an object and product. The absence of clutter is just a clutter-free product. That's not simple." - Jonathan Ive, Apple’s design chief

While designing my one and only electric bicycle five years ago, I imagined how more simple and even more basic a electric moped would look like. I decided to go for that. No pedals, no gears, no chain. Bended steel tubes for the frame, a brushless hub-motor inside the rear wheel. No petrol in the tank; instead I placed a battery inside.

A lot. The idea started with the shape of a bicycle, not a motorcycle in mind. With every step in the design process, I left out some more parts of the bike, to end with the absolute minimum.

About three years ago we started to sell the Motorman in Europe. We now sell most products in The Netherlands, Germany, France, Swiss, Belgium, Norway.

Yes, we have serious plans to come to the United States. We are working on legislation now.

The Current: Alta Motors Crapshoot Dragster

John McInnis is a designer working under Alta co-founder Jeff Sand, the Chief Design Officer and original architect of the Alta Redshift motor. McInnis came to Alta from Lightning Motorcycles, where he was responsible for Class A surface modeling on its LS-218 electric superbike that broke records at Bonneville (the '218' was its top speed on the salt) and kicked the ass of every dinosaur-powered factory racer on Pike's Peak in 2013.

At Alta, McInnis’ role bounces between surface/solid modeling, concept sketching, and a little bit of graphic design. All of which are his favorite aspects of the design process. “I definitely feel fortunate to have found myself here; it's an absolute dream job,” he told me from his office in Alta’s Brisbane, California headquarters - eight miles south of downtown San Francisco. “Alta is definitely doing some of the raddest things in motorcycling and it's great being a part of it.”

And it doesn’t get any radder than a silent dragster called the Crapshoot.

Q: John, how and when did the Crapshoot project begin?

We knew we wanted to bring another bike to The One Moto show in Portland, the question was obviously "what?" Jon Bekefy, our marketing director at the time, had challenged me to come up with something unexpected; something you wouldn't see any other electric OEMs do. We agreed it wasn't going to be a café or a scrambler, because that felt just a little too obvious. Some other ideas we threw around were an `80s GP-inspired muscle bike or a speedway bike before we landed on one of the most niche segments: vintage drag bike!

After looking through the history books, some of the builds that stood out to me were by Boris Murray with his twin-engine, fully-faired Triumph and Leo Payne, creator of the awesome "Turnip Eater" Ironhead Sportster. These guys built these fantastic machines out of garages in the `60s, and I wanted this build to reflect that "handmade-ness". My mission was to prove that a regular guy with regular tools and basic fabrication skills can take a Redshift and turn it into something pretty wild, without needing to be an electrical engineer. So in that spirit, all of the electronics and the core of a bone-stock Redshift remained unchanged.

Q: How many different versions were explored before this one was built?

I had only done a handful of pen sketches and one digital sketch before people were pretty excited about it and the rough silhouette was solidified. I had planned on it being a hardtail from the beginning, and getting it as low as possible was a priority. Once I created the hardtail section in CAD, that part stayed the same. The bodywork changed based off of what I could get in the limited time and what would fit best on a 250cc equivalent dirtbike (not much..) but the people at AirTech have quite the selection of fairings, and ended up with their AJSM5 three-piece fairing.

Q: Who laid hands on this project, and what were their contributions?

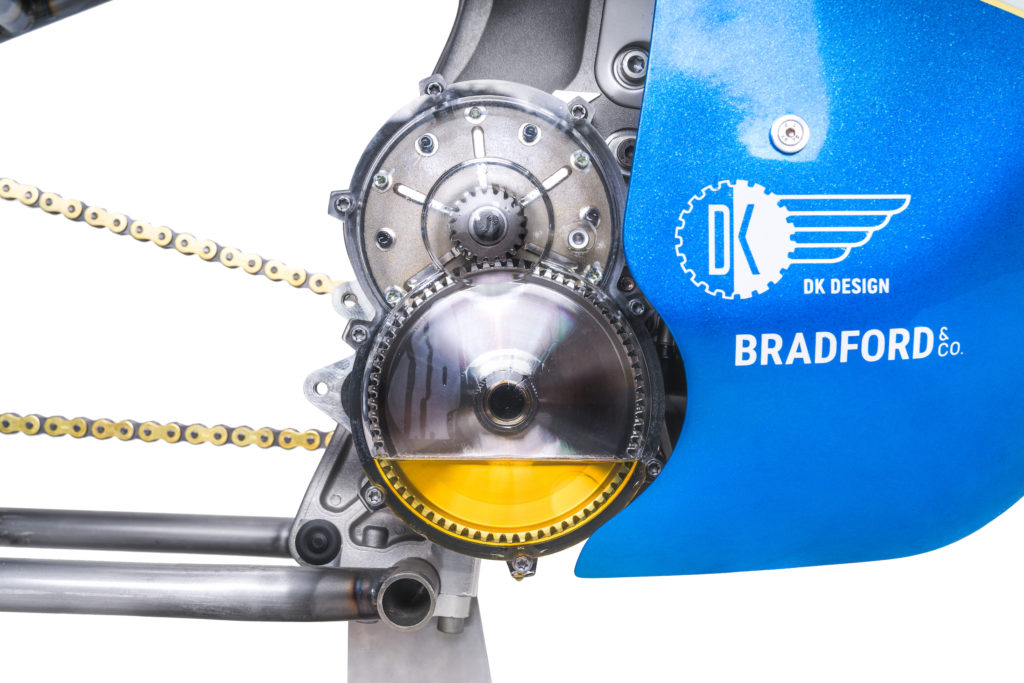

Once I had a sketch to work from, I took it to our assembly line supervisor, Vinnie Falzon, who's a proficient welder and fabricator. He was instantly excited to be part of the project and ordered material to build the hardtail that day. We bent the tubing using Jeff Sand's old Hossfeld that was in a container behind the shop. He's responsible for all the major fab work on the hardtail section, plus the sleek, hand-formed aluminum seat section that he didn't even start until about two weeks before the bike was to be displayed in Portland. [And, it should be noted, Sand's design/fabrication chops are massive; he basically invented the step-in snowboard binding at Switch - ed.]

Once I figured out the mounting brackets and trim lines for the body work, I sent the fairing to Dennis Hodges of DK Design in San Francisco, who didn't bat an eye when I told him exactly how much metal flake I wanted on this thing. He's responsible for all the clean up work and paint on the fairing, and converting it to a single piece, eliminating the unsightly part line. His accomplice, Jon Bradford, was able to turn our "crapshoot" logo into a sweet decal for the side of the bike.

The seat was a total custom job by Frances Midori, also from SF, who does a lot of work out of Hodges' shop. We basically dropped off our seat pan and said "make it look like grandpa's smoking chair" and she totally nailed it. It was the cherry on top for this little retro futuristic period piece, from the future.

Q: How many hours total were invested?

We started bending the tube for the hardtail around the middle of January, and from then until we were doing final assembly in the van on our way up to Portland was nonstop. Vinnie has 40 hours into the seat section alone and I'm pretty sure Dennis didn't sleep a few days while doing paint and bodywork. There's at least 100 total man hours into the build.